How the Design of a Part Influences the Manufacturing Process

In precision manufacturing, a part’s design lays the foundation for the entire production process. At Modelcraft Co., we recognize how critical design decisions can influence efficiency, quality, and cost. To streamline this understanding, we’ve broken down the connection between part design and manufacturing into five key steps.

Step 1: Material Selection

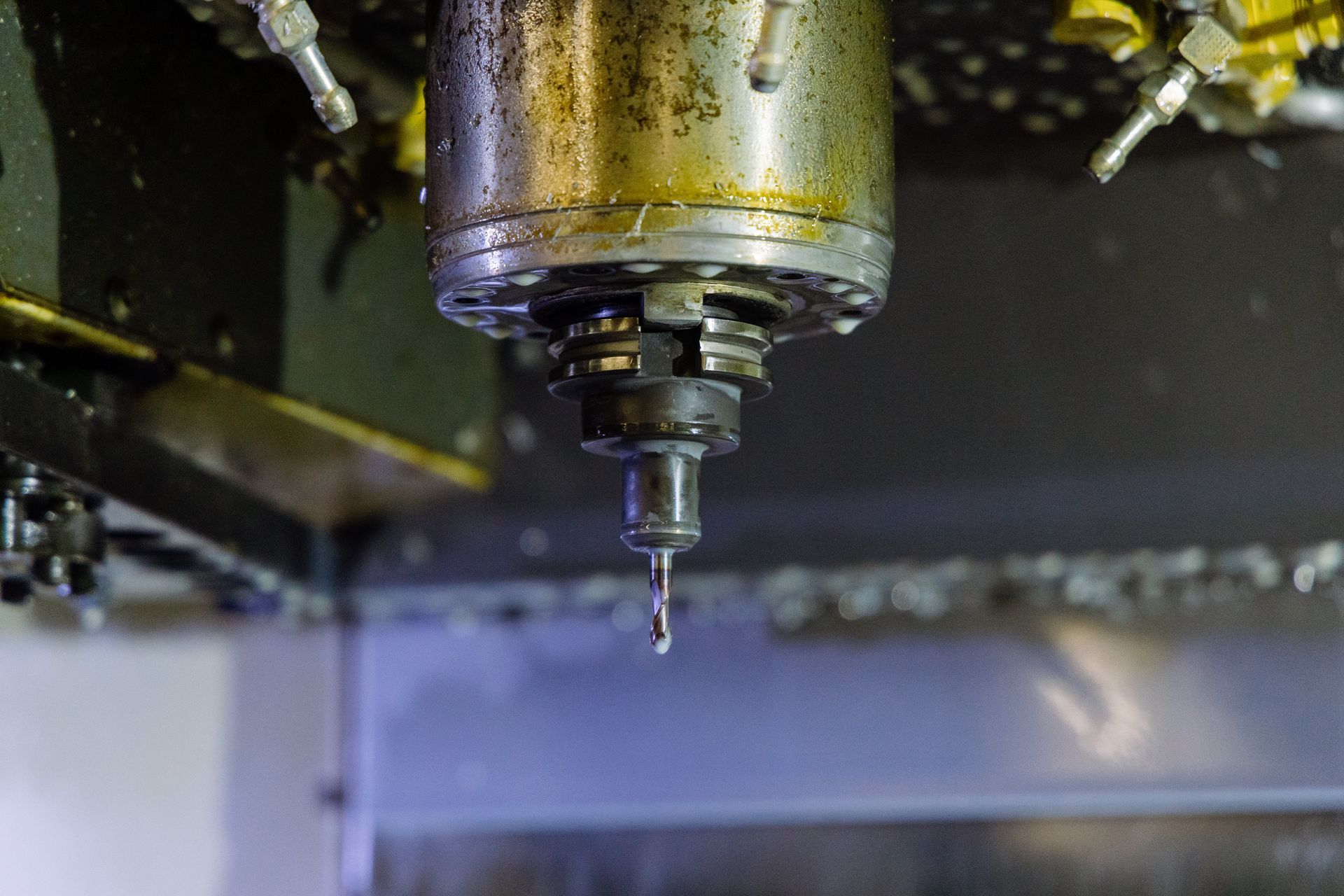

The material chosen for a part has a profound impact on how it’s manufactured. Tough materials like titanium may require advanced machining techniques, while softer materials like aluminum allow for faster machining but may require additional care to maintain precision. Material properties also dictate the tools, machines, and processes needed, influencing production costs and lead times.

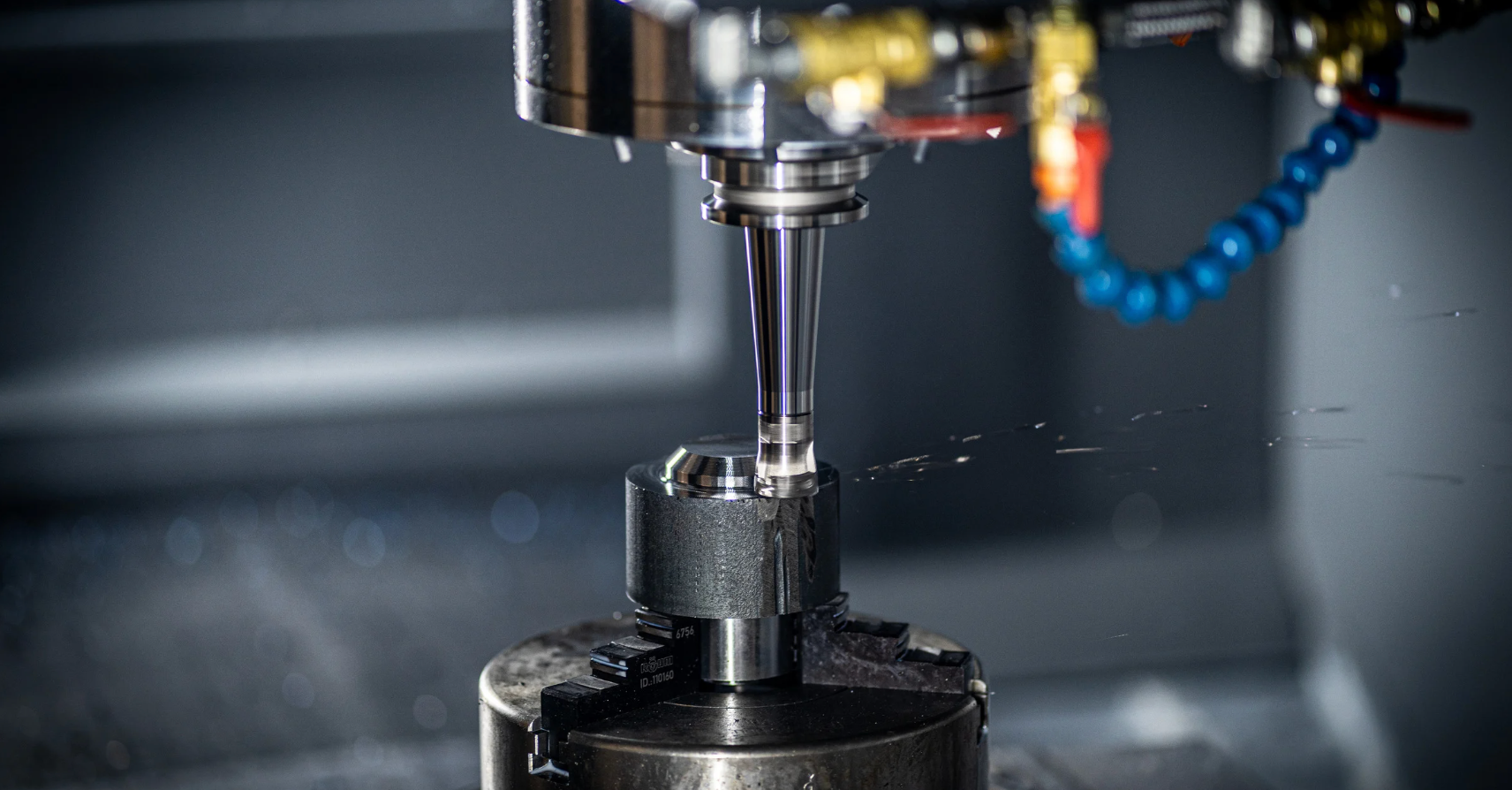

Step 2: Tolerances and Precision

The tighter the tolerances, the more advanced the manufacturing techniques required. For industries like aerospace and medical manufacturing, where precision is non-negotiable, processes such as

grinding or wire EDM are essential. These processes ensure the part meets exacting specifications, but they can increase production complexity and cost if not carefully planned.

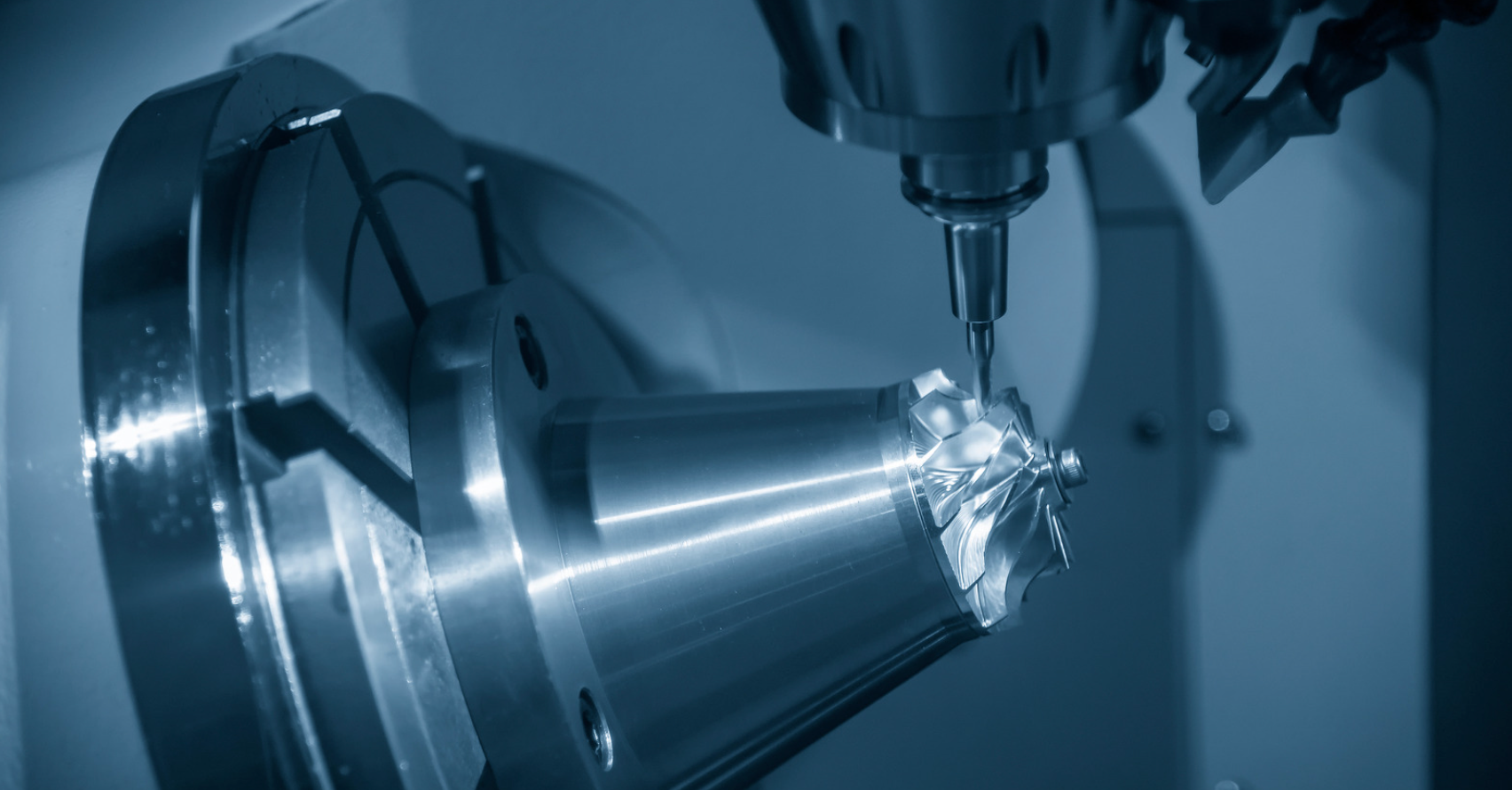

Step 3: Part Geometry

The complexity of a part’s geometry determines how it can be machined. Designs with intricate shapes, internal cavities, or thin walls may require specialized techniques like

5-axis milling or multiple machining setups. Simplifying geometries where possible can reduce production time and costs without sacrificing functionality.

Step 4: Surface Finish Requirements

A part’s required surface finish directly impacts manufacturing steps. For applications like medical devices or aerospace components, smooth or polished finishes may necessitate secondary operations such as grinding, lapping, or polishing. These steps ensure functionality and aesthetics but can add to production time and expense.

Step 5: Manufacturability Optimization

Applying

Design for Manufacturability (DFM)

principles ensures a smoother production process. By involving manufacturers like Modelcraft Co. early in the design phase, potential challenges such as tool accessibility and machining feasibility can be addressed. This collaborative approach reduces the likelihood of errors and costly redesigns, ensuring your part is optimized for efficient production.

Why Early Collaboration is Key

At Modelcraft Co., we understand that great manufacturing starts with great design. Collaborating early in the design phase allows us to offer insights and recommendations that improve manufacturability without compromising innovation. With almost 60 years of experience, we specialize in turning complex designs into high-quality, precision-manufactured parts.

Contact Modelcraft Co. Today

The design of a part is more than just a concept—it’s a roadmap for manufacturing success. By focusing on material selection, precision requirements, geometry, surface finish, and manufacturability optimization, you can streamline production while maintaining quality and efficiency.

Ready to bring your designs to life?

Contact Modelcraft Co. today at

(860) 453-9493 to partner with a trusted leader in precision manufacturing.

Recent Articles