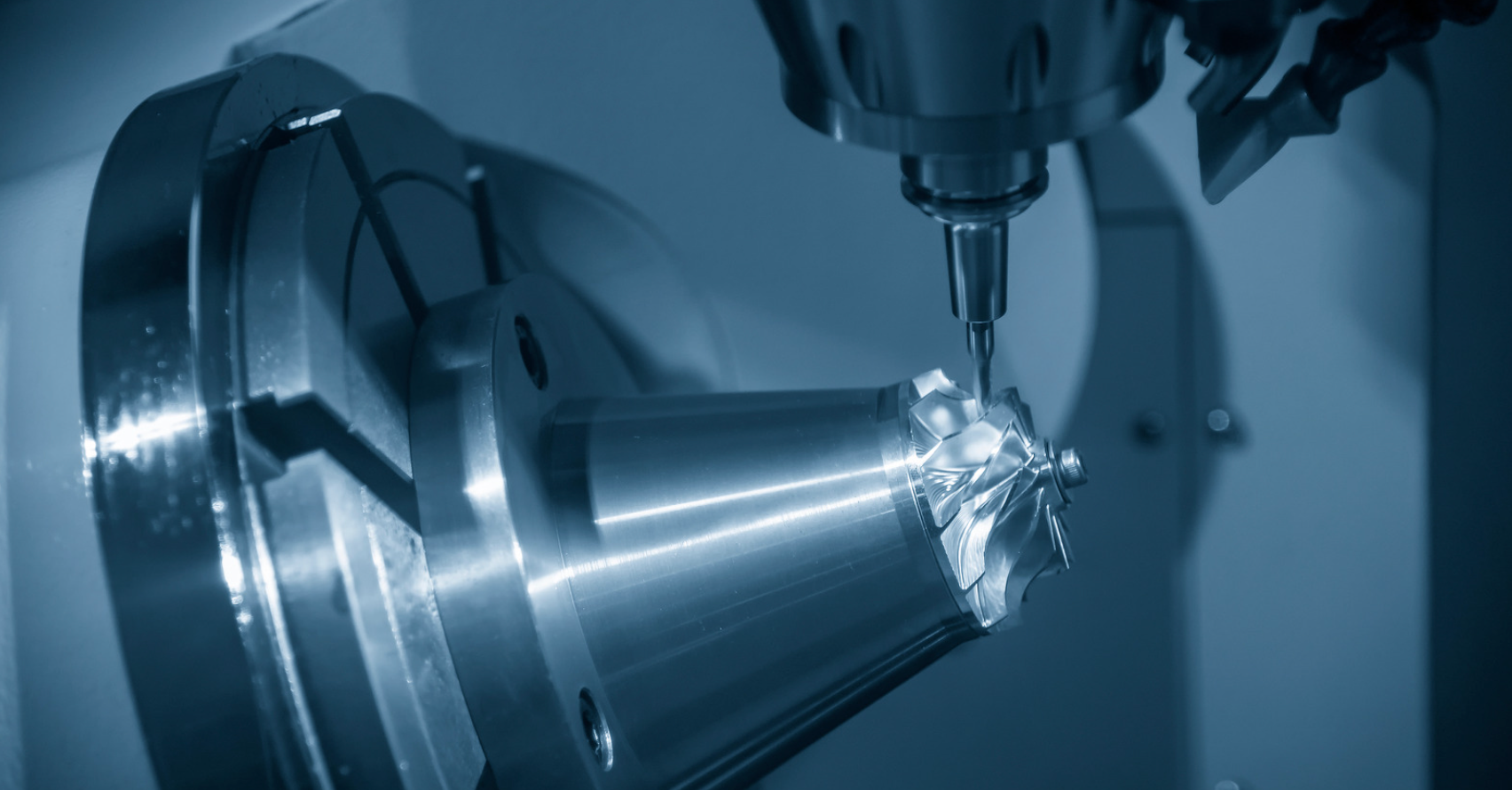

Make the Most of Your Five-Axis Machine

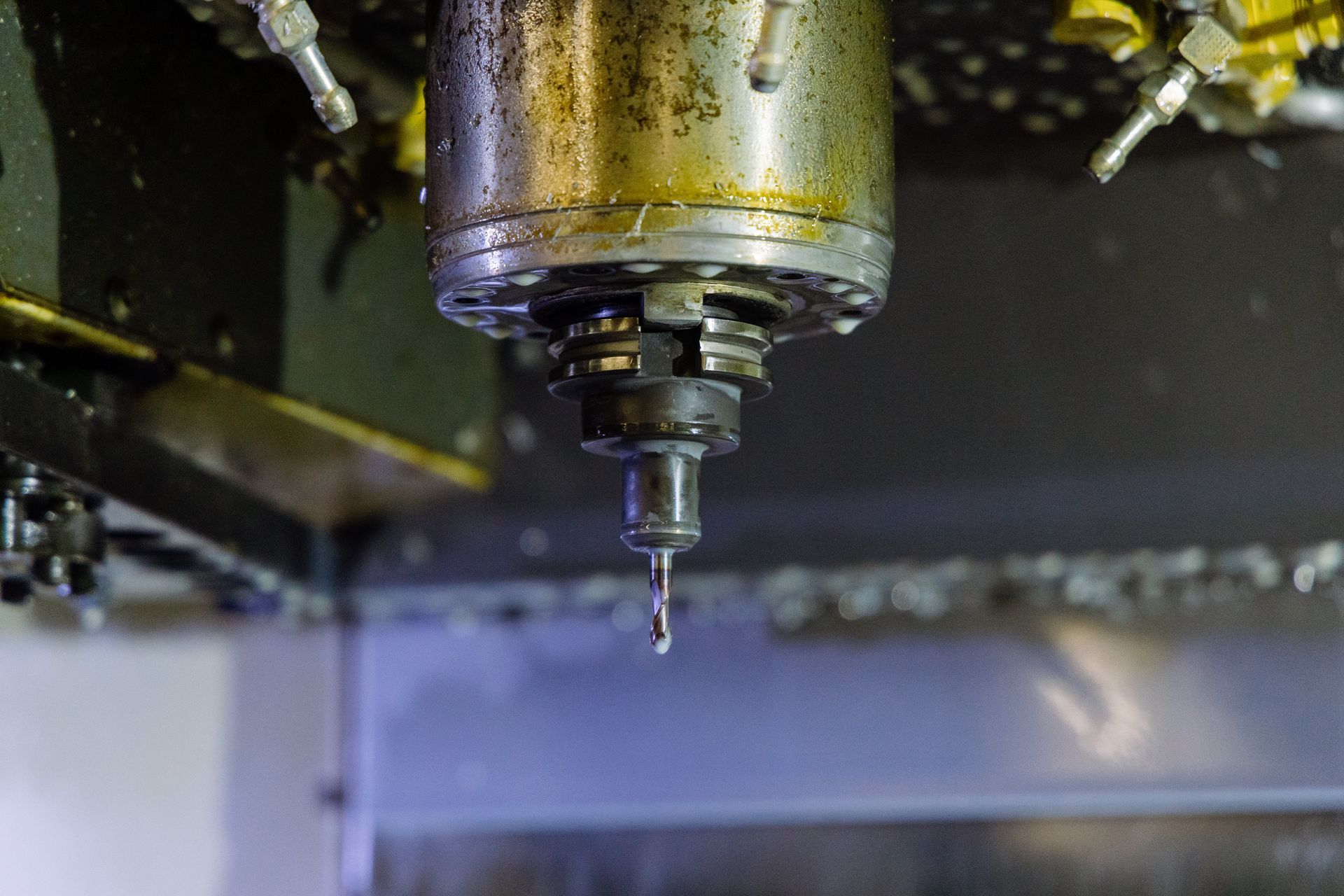

Five-axis machining is a game-changer in the manufacturing world, especially for industries that demand precision, like aerospace, medical, and commercial manufacturing. This advanced technology allows manufacturers to create complex parts with high precision and efficiency, but unlocking its full potential requires strategic planning and attention to detail. Here, we’ll share tips to help you make the most of your five-axis machine.

1. Optimize Tool Paths

Efficient tool paths are essential to get the most from your five-axis machine. Using CAM software tailored for five-axis machining can optimize tool paths, minimizing unnecessary movements and reducing cycle times. Not only does this boost productivity, but it also extends tool life by reducing wear and tear.

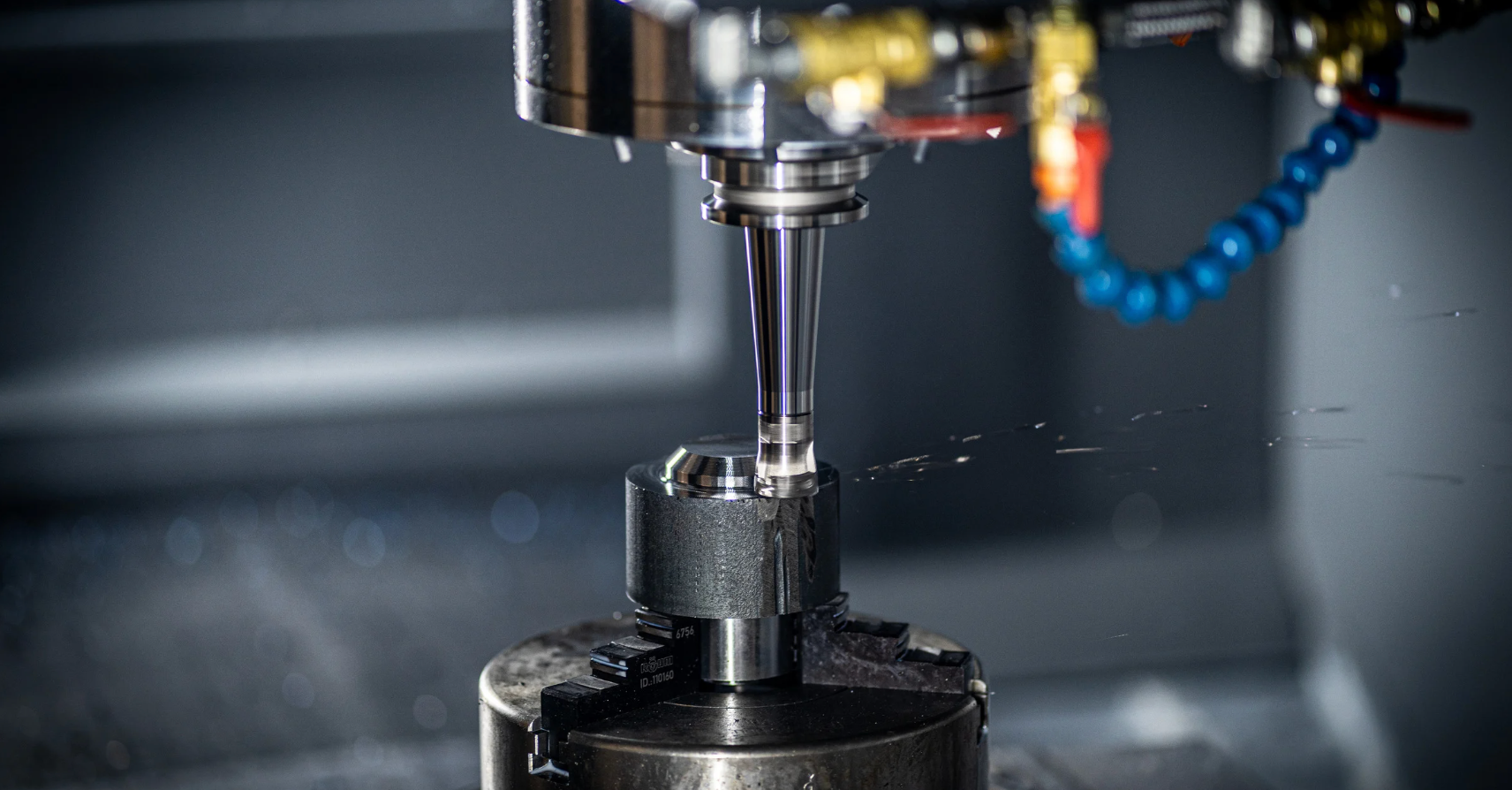

2. Use High-Quality Tools

The right cutting tools are crucial for precision and speed. High-quality tools made from durable materials like carbide, with advanced coatings, can handle the demands of five-axis machining better than standard tools. This investment in quality tools can lead to faster production speeds, improved accuracy, and longer tool life.

3. Embrace Adaptive Machining

Adaptive machining techniques, such as dynamic milling, are designed to reduce tool wear by maintaining a constant chip load. This approach allows for faster feeds and speeds, making it ideal for five-axis machines, where maintaining steady engagement with the material enhances both precision and efficiency.

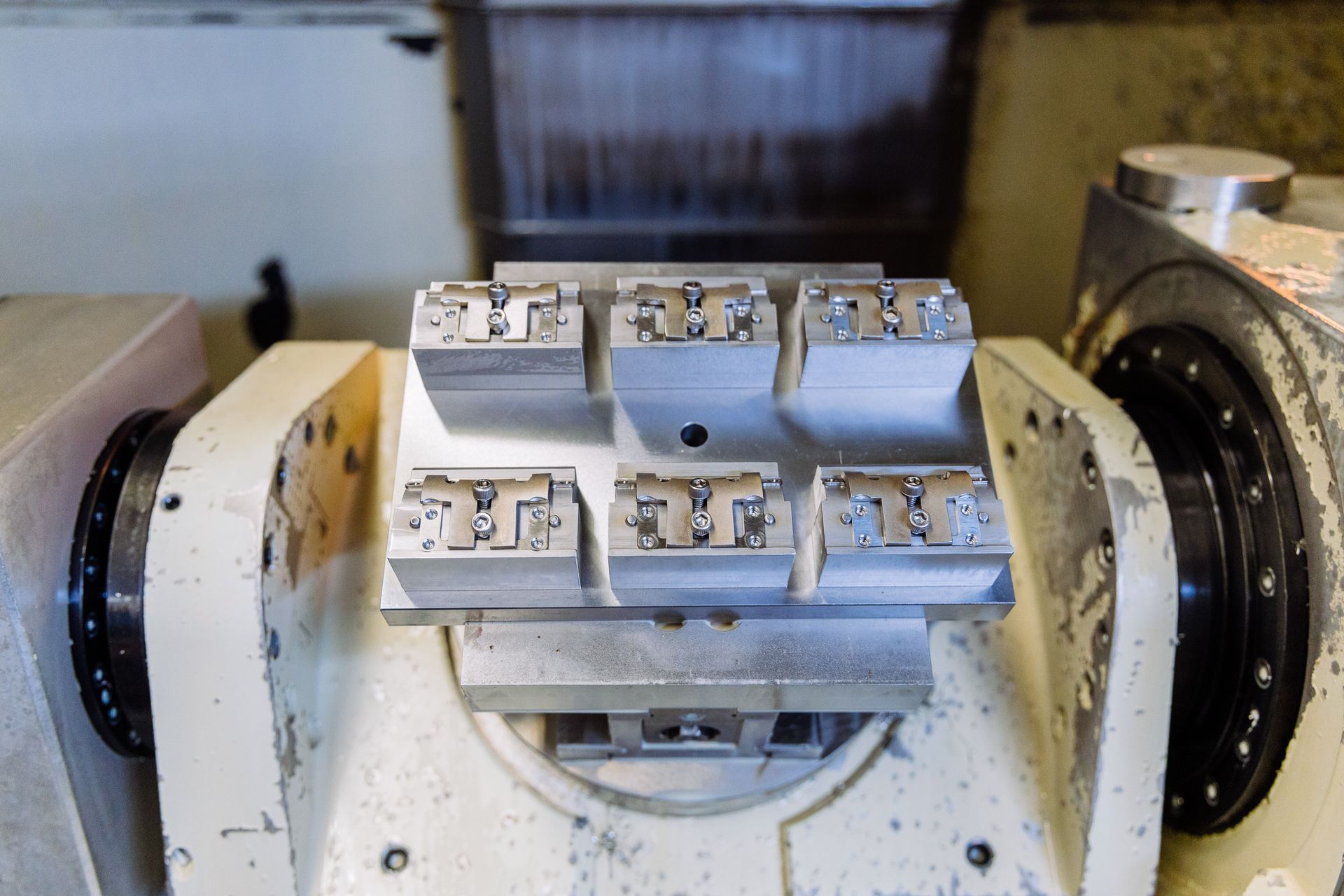

4. Prioritize Fixture Design

A secure fixture setup is essential for five-axis machining. Modular or custom-designed fixtures help reduce vibration and misalignment, improving accuracy and allowing for more complex geometries. Taking the time to perfect your fixture design will result in better part quality and reduced cycle times.

5. Invest in Training

Five-axis machining requires a specialized skill set. Investing in training for your team ensures they understand the unique aspects of programming, setup, and operation of five-axis machines. Many manufacturers offer training programs, and investing in continuous education for your staff will enhance productivity and precision.

At Modelcraft Co., we leverage our five-axis machines to deliver high-quality, precision components that meet our clients’ needs. With nearly 60 years of experience in the industry, we understand that maximizing the capabilities of advanced machinery is key to maintaining a competitive edge. Following best practices like tool path optimization, quality tooling, adaptive machining, improved fixturing, and focused training can help you fully realize your five-axis machine’s potential.

For precision manufacturing solutions,contact Modelcraft Co. and let’s make the most of your five-axis machine together.

Recent Articles