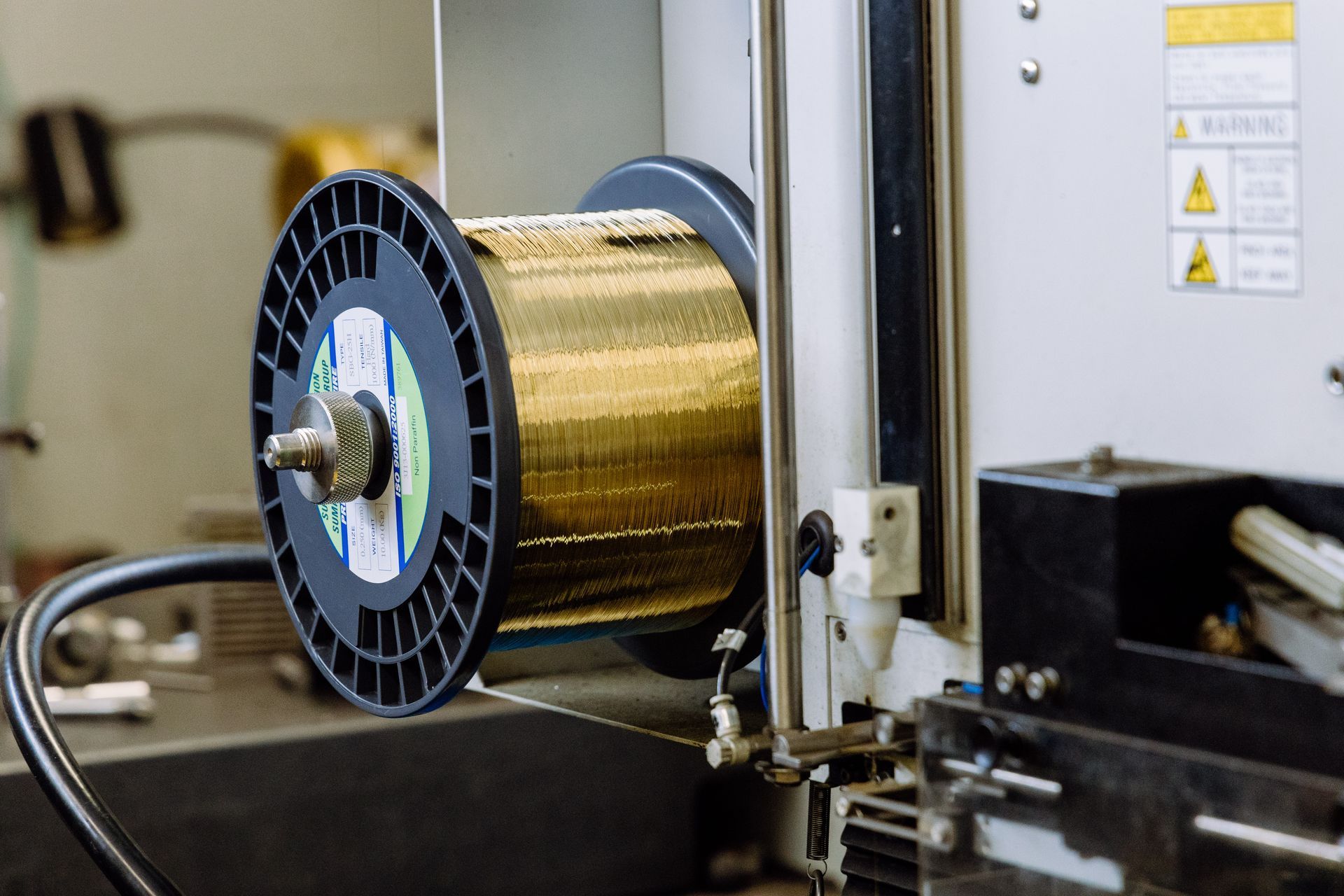

Precision Wire EDM Capabilities

Enhancing Manufacturing with Wire EDM in Connecticut

Wire Electrical Discharge Machining (Wire EDM) is a cornerstone of Modelcraft’s advanced machining capabilities. Our Wire EDM services offer unparalleled precision, making it the preferred choice for intricate cuts, complex shapes, and delicate features that conventional machining cannot achieve. With the ability to machine any conductive material with extraordinary accuracy, our Wire EDM process is essential for producing high-precision components.

Whether you require high precision for aerospace components, intricate patterns for medical devices, or complex shapes for specialized tooling, Modelcraft’s Wire EDM services are equipped to meet your needs with unparalleled precision. Get in touch with us today to discuss how our Wire EDM capabilities can contribute to the success of your next project.

Core Competencies

Our specialized skills set Modelcraft Co. apart from the competition and fuel our success.

Milling

Turning

Grinding

Assembly

Industries We Serve

Modelcraft Co. provides specialized services to a wide range of industries. Find your industry to see how we can help.

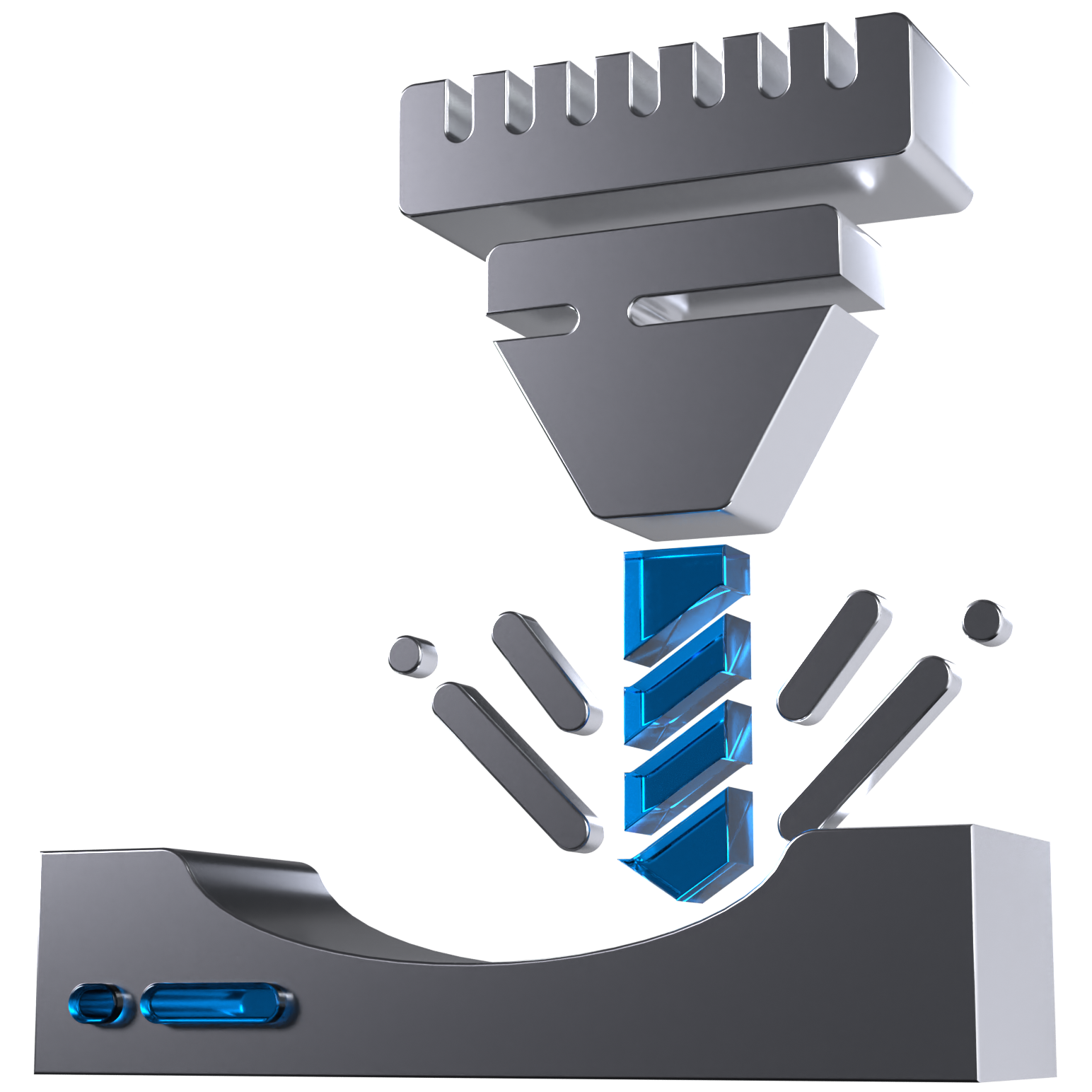

Our Wire EDM Process

Consultation

Every Wire EDM project begins with an in-depth consultation to understand the unique requirements of your design.

Material Selection

We carefully select the optimal conductive material to ensure quality and performance for your specific application.

Design Programming

Utilizing state-of-the-art CAD/CAM software, we meticulously program the Wire EDM path for ultimate precision.

Setup & Calibration

Our machines are expertly set up and calibrated, laying the groundwork for flawless execution.

Wire EDM Cutting

The wire precisely slices through the material, sculpting intricate components with razor-sharp accuracy.

Deburring & Finishing

After cutting, components are deburred and finished to achieve a superior surface quality.

Quality Inspection

A final, stringent quality inspection is conducted, affirming that every component meets the project’s exacting standards.

Why Choose Modelcraft Co.

Our key areas of expertise that set us apart in the industry.

Over 55 Years of Industry Experience

AS 9100 Manufacturing Supplier

Award-Winning Small Business

Dedicated & Diligent Team Members

High-Quality Turnkey Solutions

Quality Components & Automations

What Our Clients Say

We are proud to work with some amazing clients. Here’s what they have to say about us.

"Quality is a reason we continue choosing Modelcraft- we value suppliers that provide high-quality products, and that’s what they give us."

- Ron Curtin, Hoffman Engineering

"We've been working with Modelcraft for over 10 years. Their service is very reliable. They offer good quality, good prices, and good turnaround times."

- Tom Addy, Quality Engineering

"Modelcraft has a strong sense of understanding in the parts and what it takes to make them well at a competitive price, and they have a high level of communication."

- Jeff S., Siemens Health