8 Reasons Why CNC Precision Machining Is So Important

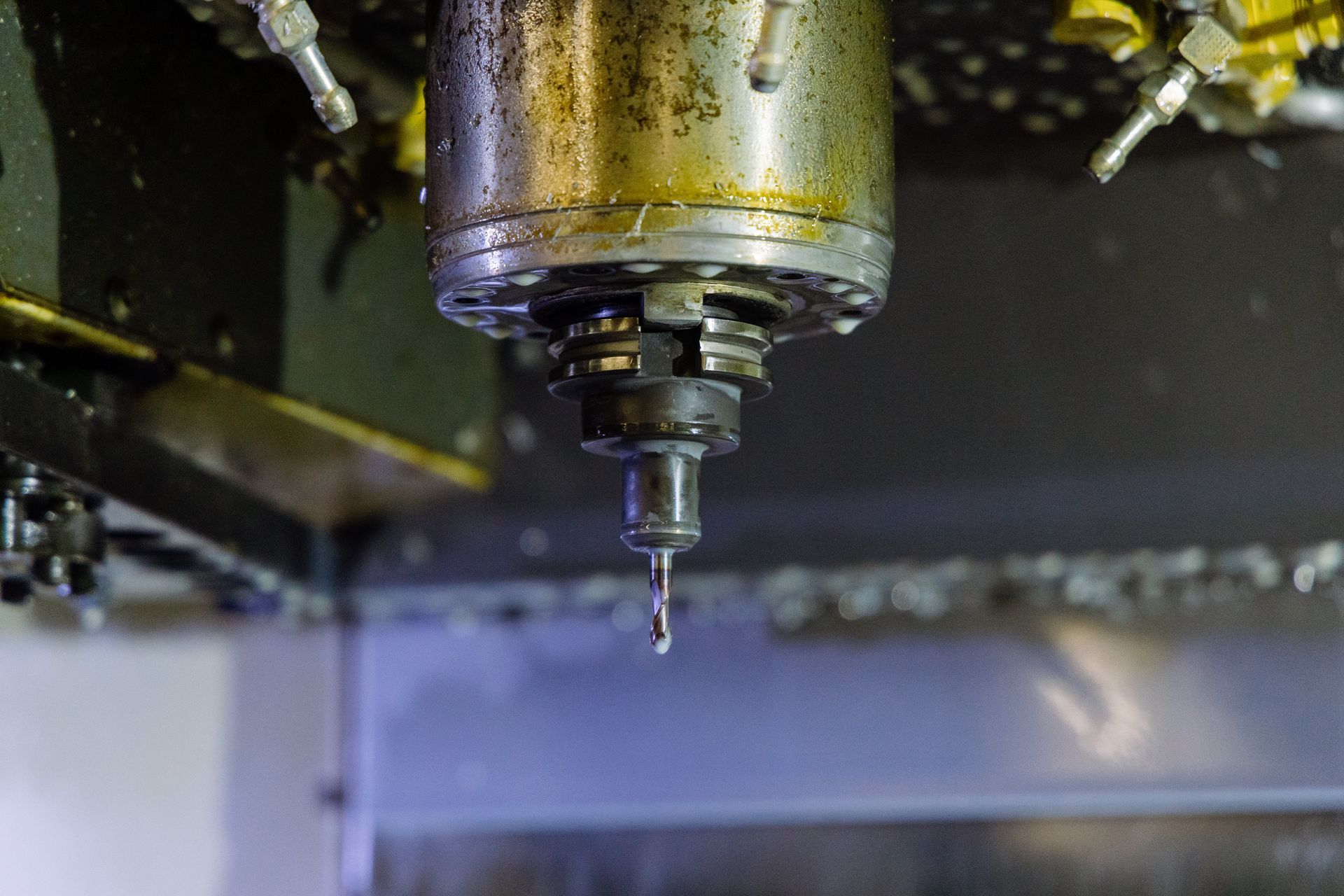

In today’s highly competitive manufacturing world, precision is no longer a luxury — it’s a necessity. Whether in aerospace, medical devices, or commercial components, delivering parts that meet the strictest tolerances is essential for performance, safety, and customer satisfaction. That’s where CNC precision machining comes in. At Modelcraft Co., we’ve spent nearly 60 years mastering the art of precision machining. Here’s why CNC precision machining is so important — not just for us, but for the industries we serve.

1. Unmatched Accuracy and Repeatability

CNC (Computer Numerical Control) machining allows for incredible accuracy, often within thousandths of an inch. Whether you’re producing a single prototype or thousands of components, CNC machines ensure every part meets exact specifications, again and again. This repeatability is critical for industries like medical and aerospace, where failure is simply not an option.

2. Improved Efficiency and Speed

Because CNC machines are automated and programmed to follow precise instructions, they dramatically reduce production time. Complex parts that would take days to make manually can often be completed in hours. At Modelcraft Co., our investment in updated equipment helps us deliver projects faster without sacrificing quality.

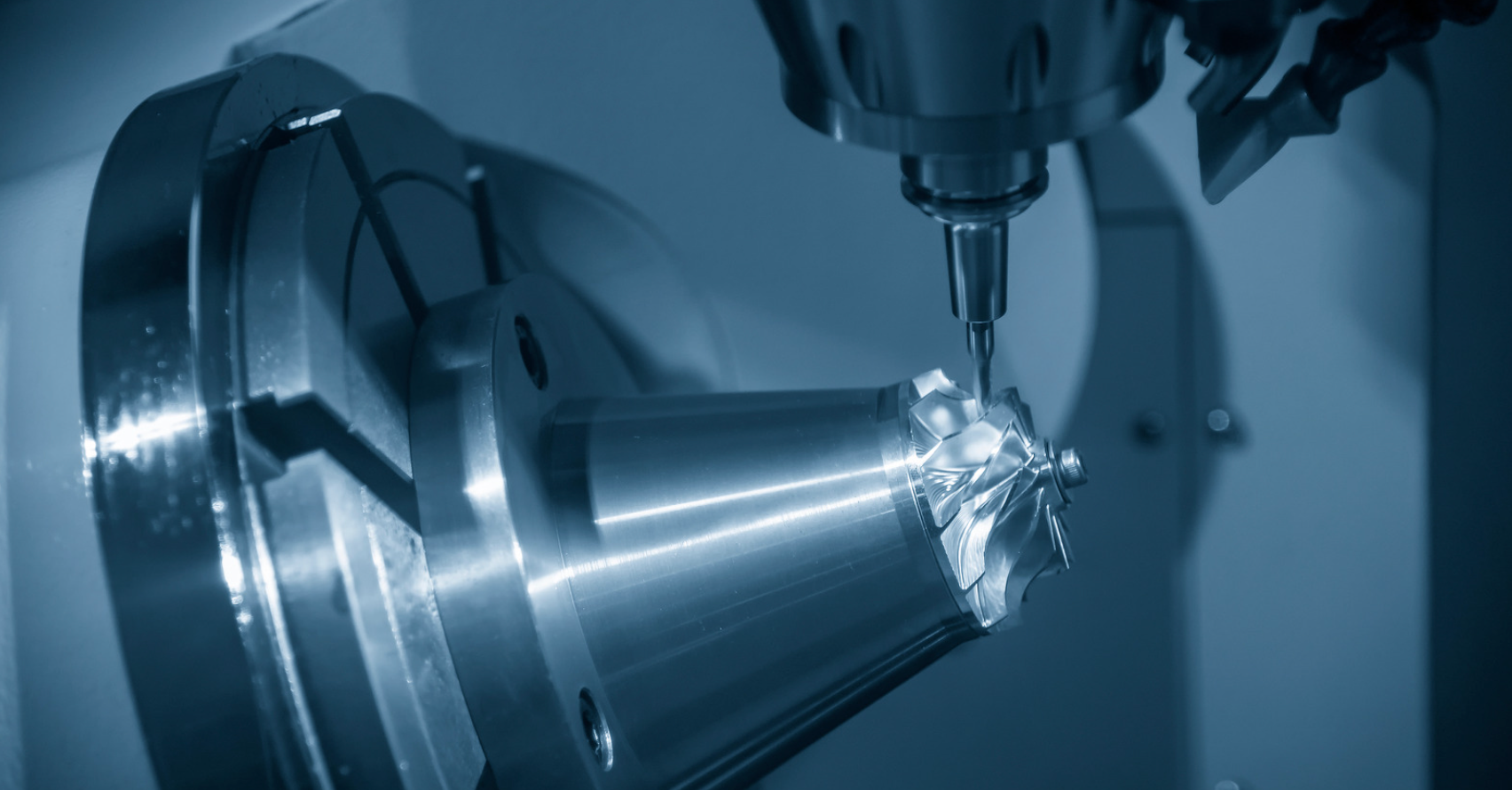

3. Complex Geometries Made Possible

Modern designs often require complex shapes and geometries that are impossible to achieve with manual machining. CNC precision machining makes it possible to manufacture these intricate parts with perfect consistency — opening the door for innovation in everything from surgical tools to aerospace components.

4. Superior Quality Control

With CNC precision machining, quality control is built into the process. Automated inspection and in-process checks ensure parts meet design specifications, reducing the risk of defects. At Modelcraft Co., we back this up with full inspections and detailed documentation to give our customers complete confidence in every order.

5. Cost-Effectiveness in High-Volume Production

Although CNC machining requires an initial investment in programming and setup, it pays off in high-volume production. The automation reduces labor costs, minimizes material waste, and boosts productivity, ultimately delivering better value to customers.

6. Enhanced Material Capabilities

CNC machines can handle a wide range of materials — from aluminum and stainless steel to exotic alloys and engineered plastics. This flexibility allows manufacturers to choose the best material for performance without worrying about machinability issues.

7. Supports Innovation and Customization

CNC machining enables rapid prototyping and the ability to customize components without major retooling. This supports innovation across industries, helping companies bring new products to market faster. Our team at Modelcraft Co. specializes in collaborating closely with clients to solve their toughest manufacturing challenges, from custom parts to turnkey solutions

8. Compliance With Industry Standards

Industries like aerospace and medical devices have strict regulatory requirements. CNC precision machining plays a vital role in achieving compliance. Modelcraft Co. is proud to be AS9100D and ISO 9001:2015 certified, which means our CNC processes are aligned with the highest global standards.

Let's Build Something Exceptional Together

CNC precision machining isn’t just a manufacturing technique — it’s the backbone of modern production. It ensures the accuracy, efficiency, and reliability that industries depend on to succeed. At Modelcraft Co., we’re passionate about delivering precision-machined parts that help our customers innovate, compete, and win. Get in touch with our team today to learn more about how we can help you.

Recent Articles