The Role of 5-Axis CNC Machining in the Medical Industry

The medical industry demands innovation, precision, and reliability — often all at once. From life-saving implants to intricate surgical tools, medical components must meet the highest standards of accuracy, safety, and performance. At the heart of manufacturing many of these critical devices is 5-axis CNC machining — a technology that has transformed how the medical industry approaches complex part production. At Modelcraft Co., we combine nearly 60 years of precision manufacturing experience with advanced 5-axis CNC capabilities to help the medical industry solve its toughest manufacturing challenges. Here’s a closer look at why 5-axis CNC machining plays such a vital role in healthcare today.

1. Unmatched Precision for Life-Saving Components

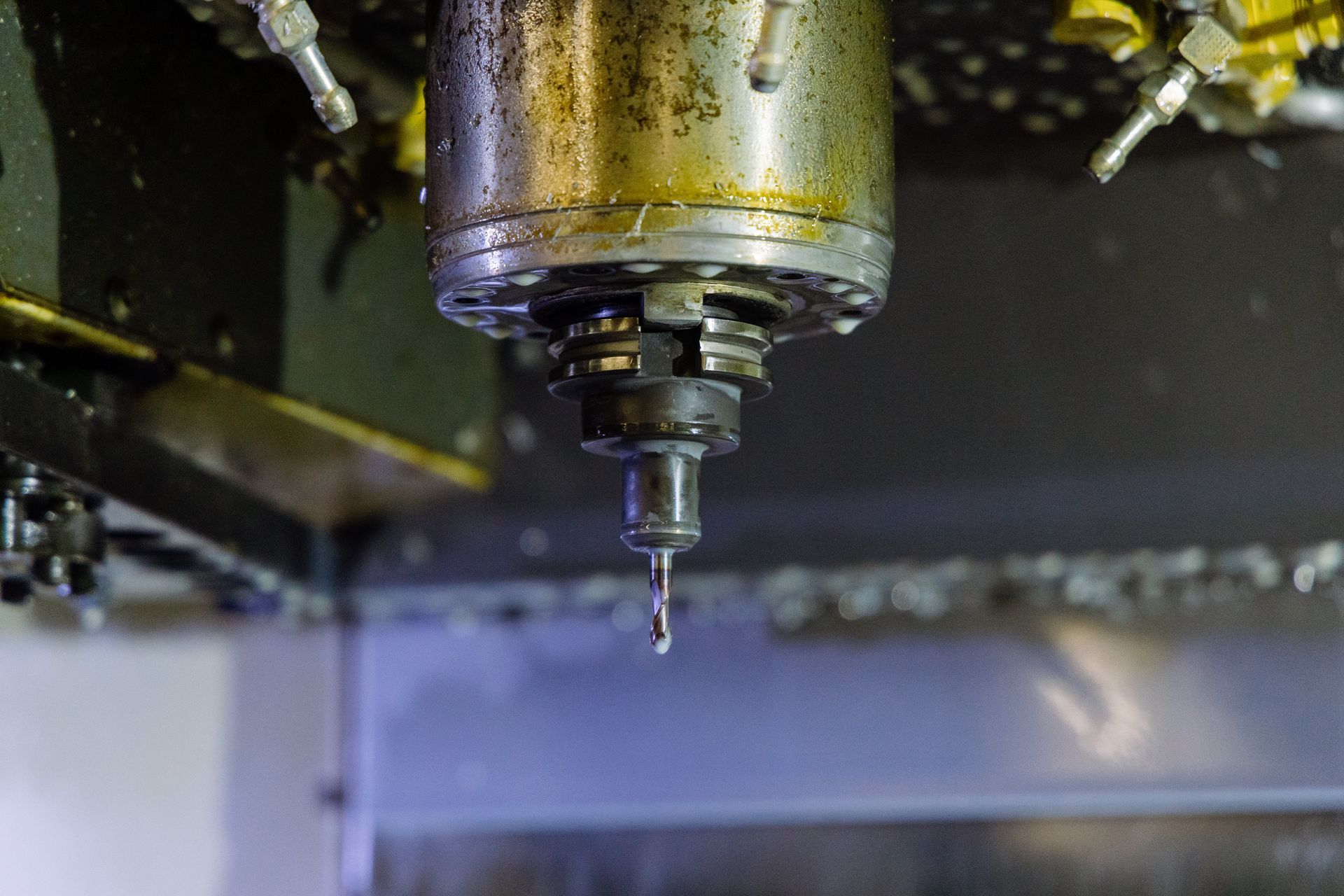

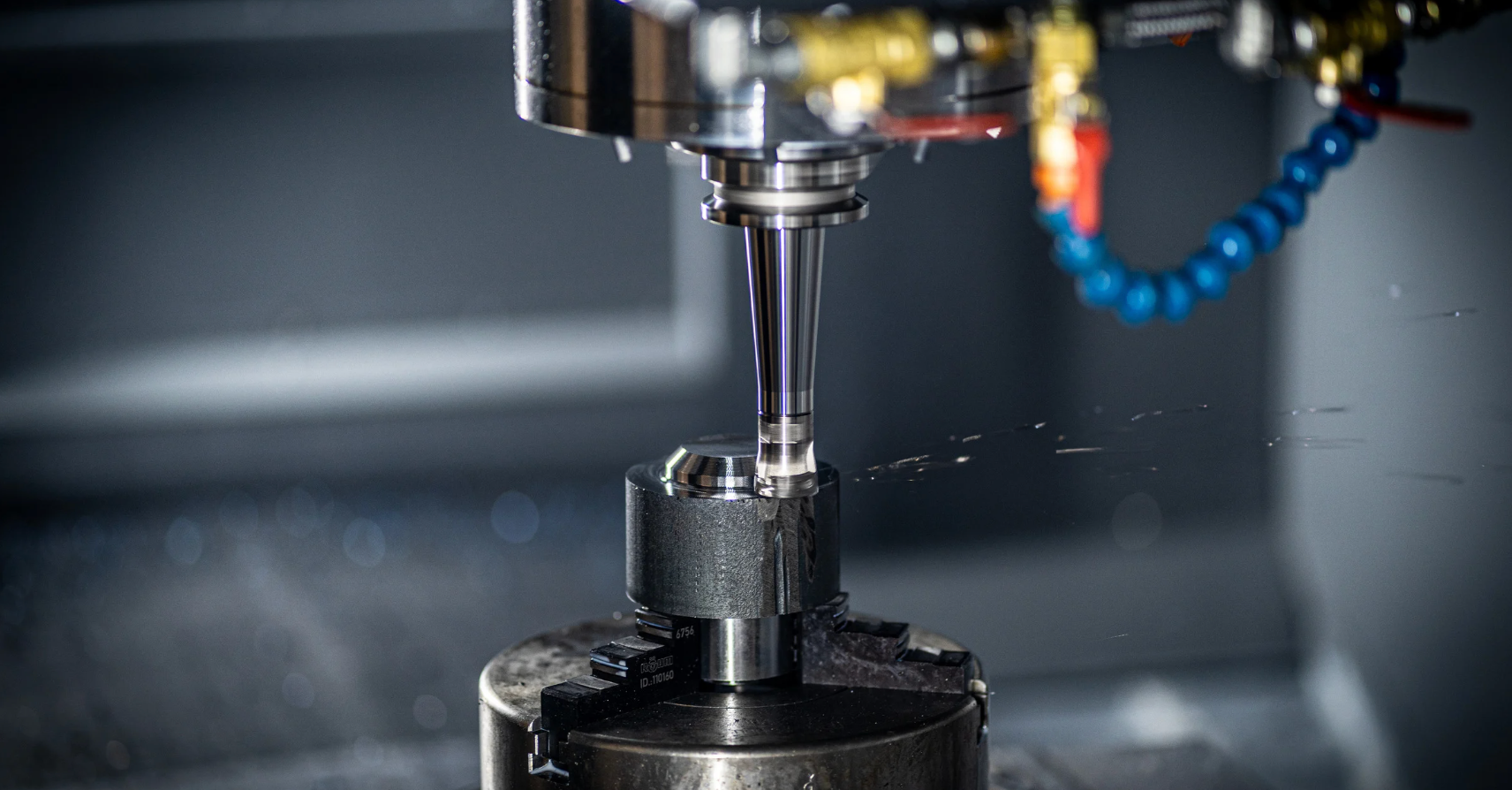

Medical components like orthopedic implants, spinal devices, and surgical instruments require extreme precision. Even the smallest deviation can compromise patient safety or device functionality. 5-axis CNC machining offers unparalleled accuracy, allowing manufacturers to achieve tight tolerances — often within microns — that are critical for medical applications. By simultaneously moving a part along five axes, this technology enables precise tool positioning and cutting angles, reducing the need for multiple setups and minimizing error.

2. Enabling Complex Geometries and Advanced Designs

Modern medical devices are becoming increasingly sophisticated, with organic shapes, undercuts, and intricate features that improve functionality and patient outcomes. Traditional machining methods struggle to achieve these designs efficiently.

5-axis CNC machines excel at producing complex geometries in a single setup. Whether it’s the curved surfaces of a knee implant or the fine features of a microsurgical tool, 5-axis technology allows medical manufacturers to bring advanced designs to life with efficiency and repeatability.

3. Improved Surface Finish and Reduced Post-Processing

For medical devices, surface finish is just as important as dimensional accuracy — particularly when it comes to implants and tools that come into contact with the human body. Poor surface finishes can lead to friction, wear, or even rejection by the body.

5-axis CNC machining minimizes repositioning and clamping, which reduces vibration and improves surface finishes right off the machine. This leads to smoother parts, reduces the need for manual polishing, and speeds up production timelines — critical in an industry where lead times matter.

4. Versatility Across Materials

The medical industry relies on a wide range of materials, from titanium and stainless steel to PEEK and other biocompatible plastics. 5-axis CNC machines are capable of handling these challenging materials with precision, enabling manufacturers to select the ideal material for each application without worrying about machinability constraints.

At Modelcraft Co., we specialize in working with a broad range of medical-grade materials, combining advanced machining capabilities with deep material expertise.

5. Faster Prototyping and Time-to-Market

Innovation moves fast in healthcare, and companies need to bring new products to market quickly. 5-axis CNC machining supports rapid prototyping by enabling the quick production of complex parts with minimal setup changes. This accelerates product development cycles and allows medical device manufacturers to test, refine, and launch new devices faster.

Precision You Can Trust in Every Medical Component

5-axis CNC machining has become an indispensable tool in the medical industry, enabling the production of highly precise, complex, and reliable components that improve patient care. At Modelcraft Co., we are proud to partner with medical companies to deliver cutting-edge solutions that meet the most demanding quality and performance standards. Get in touch with us today to learn more.

Recent Articles