How Has CNC Machining Evolved Over the Years?

CNC machining is at the heart of modern manufacturing, powering industries from aerospace to medical and beyond. But how did we get here? The CNC machines we see today — precise, automated, and incredibly sophisticated — are the result of decades of innovation and technological progress. At Modelcraft Co., with nearly 60 years of experience in precision manufacturing, we’ve had a front-row seat to this evolution. Here’s a look at how CNC machining has transformed over the years and what it means for the industries we serve today.

1. The Origins: From Manual Machining to Numerical Control

Before CNC, machining was entirely manual. Skilled machinists operated lathes, mills, and grinders by hand, relying on their experience and craftsmanship to shape parts. While this worked well for simple parts, it limited speed, consistency, and complexity. In the 1940s and 1950s, the first numerical control (NC) systems emerged, using punched tape or cards to guide machine movements. This breakthrough allowed manufacturers to automate simple tasks, dramatically improving repeatability and precision.

2. The Birth of CNC: Computers Take Control

In the 1960s and 1970s, NC systems merged with computers, giving rise to computer numerical control (CNC) machining. With CNC, machines could interpret digital code (like G-code) to control movement, speed, tool changes, and more — all with minimal human intervention. For Modelcraft Co., founded in 1965, this was a pivotal era. As the technology matured, we invested in CNC capabilities to deliver higher precision, faster turnaround times, and greater production flexibility to our customers.

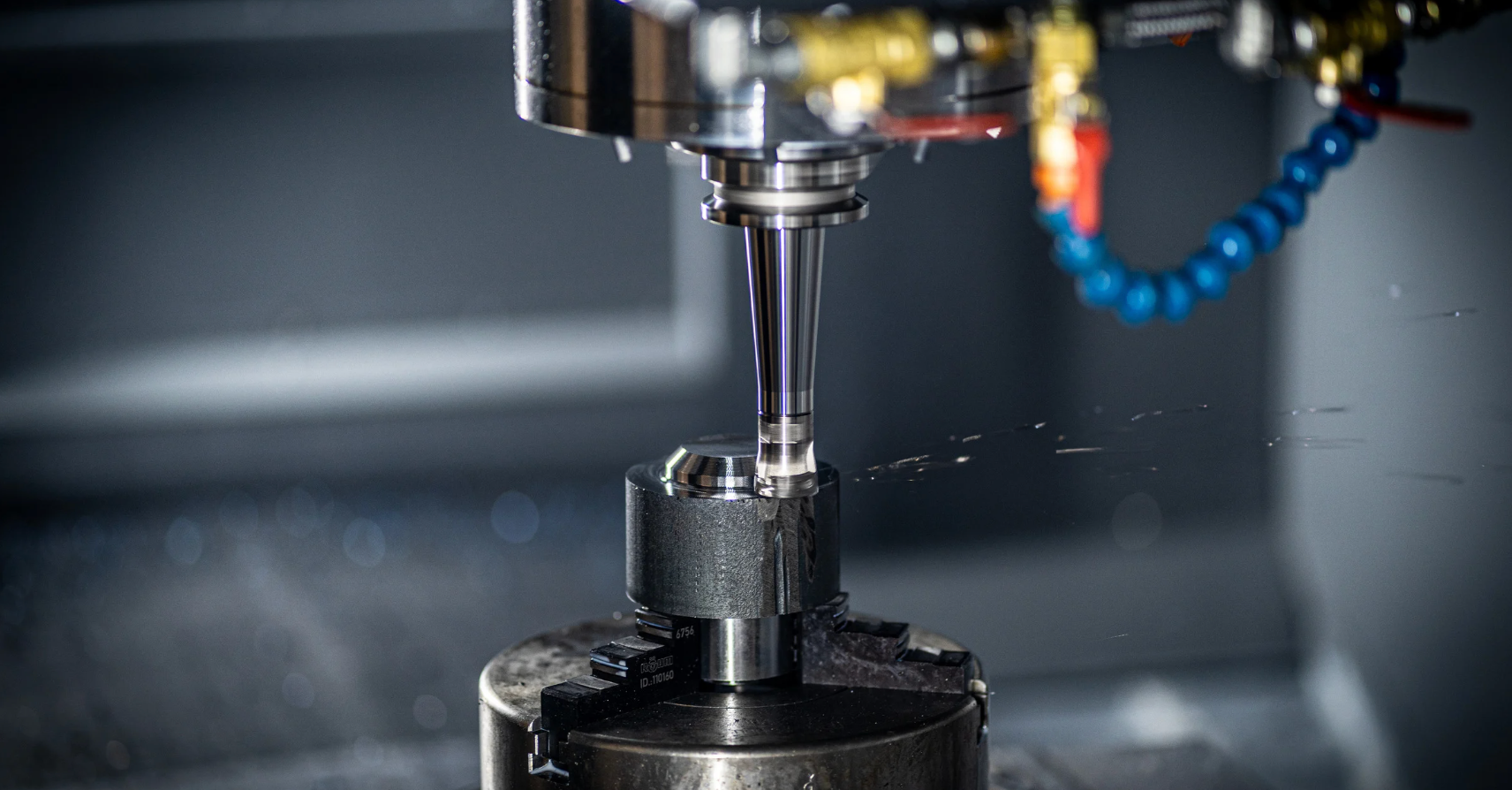

3. The Rise of Multi-Axis Machining

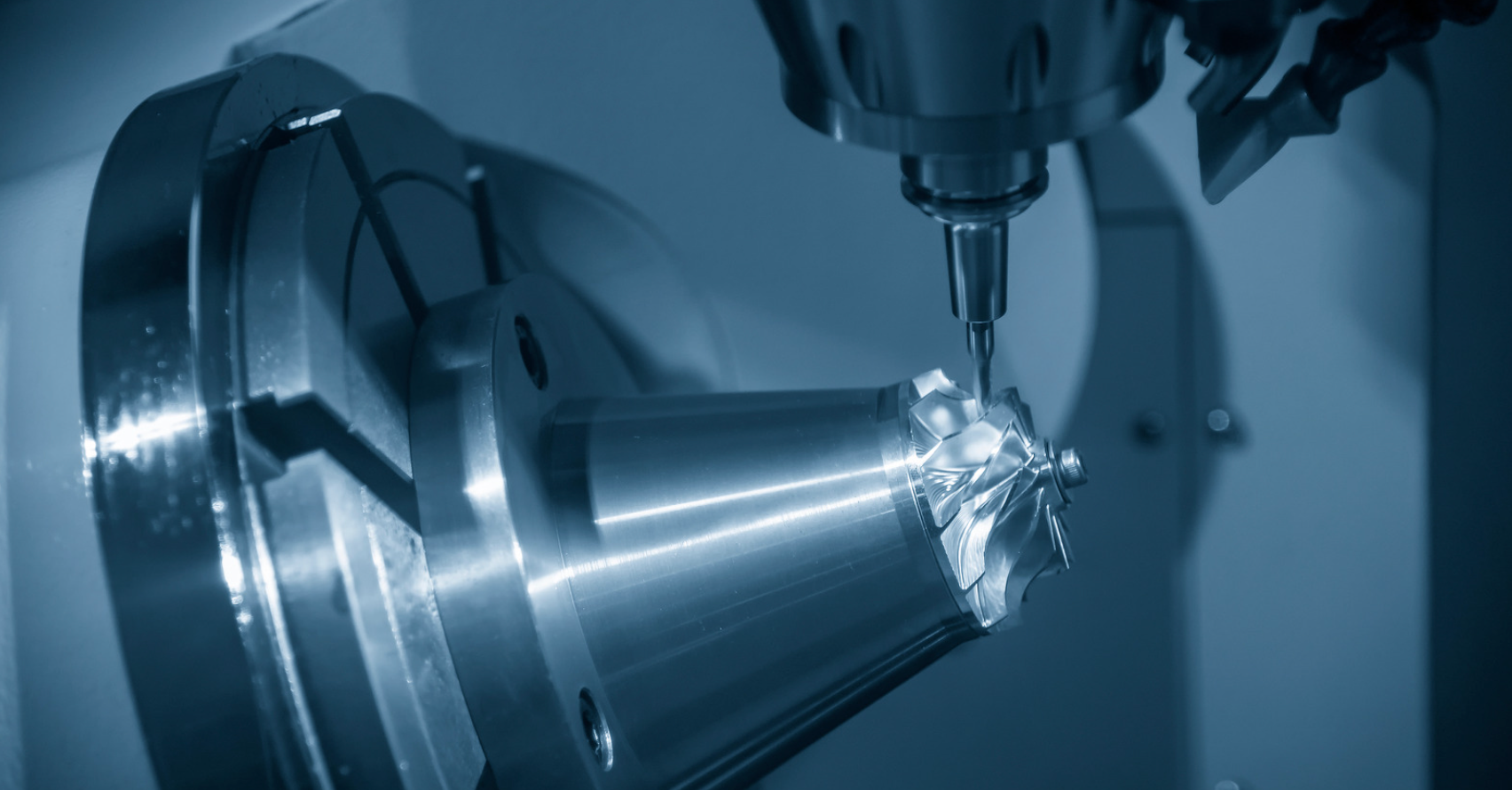

Early CNC machines were typically 2- or 3-axis, meaning they could move in basic X, Y, and Z directions. But as part designs grew more complex, so did the machines.

4-axis and 5-axis CNC machines emerged, allowing tools and parts to rotate and tilt, making it possible to machine complex geometries in a single setup. This was a game changer for industries like aerospace and medical, where intricate shapes and tight tolerances are critical. Today, at Modelcraft Co., our advanced multi-axis CNC equipment enables us to manufacture components with unmatched precision and efficiency.

4. Software and Simulation: Smarter, Faster Machining

Modern CNC machining isn’t just about the machines — it’s about the software behind them. Computer-aided design (CAD) and computer-aided manufacturing (CAM) tools allow engineers to design, simulate, and program machining operations digitally before they ever touch a piece of metal. Simulation reduces trial and error, minimizes material waste, and shortens production timelines — a huge leap from the days of manual setups and paper blueprints.

5. Automation and Industry 4.0

Today’s CNC shops are increasingly automated, with robotics, pallet changers, and automated inspection systems seamlessly integrated into production lines. Combined with data analytics and real-time monitoring (known as Industry 4.0), manufacturers can optimize performance, predict maintenance needs, and ensure consistent quality. At Modelcraft Co., we’ve embraced these technologies to help our customers stay ahead of the curve, providing turnkey solutions that deliver precision, speed, and reliability.

6. What’s Next for CNC Machining?

The future of CNC machining looks bright. We’re seeing advances in artificial intelligence, machine learning, additive manufacturing (3D printing), and hybrid systems that combine multiple processes into a single machine. For manufacturers like Modelcraft Co., the mission remains clear: to keep investing in new technologies, stay ahead of industry demands, and continue delivering precision-machined parts that exceed expectations.

Partner With a Shop That’s Evolved With the Industry

CNC machining has come a long way — from manual mills to intelligent, multi-axis systems that shape the future of manufacturing. At Modelcraft Co., we’re proud to have been part of this journey and excited to help our customers navigate the next era of innovation. Get in touch today to learn more.

Recent Articles