What Are the Key Factors That Affect CNC Machining Costs?

What Are the Key Factors That Affect CNC Machining Costs?

Material Selection

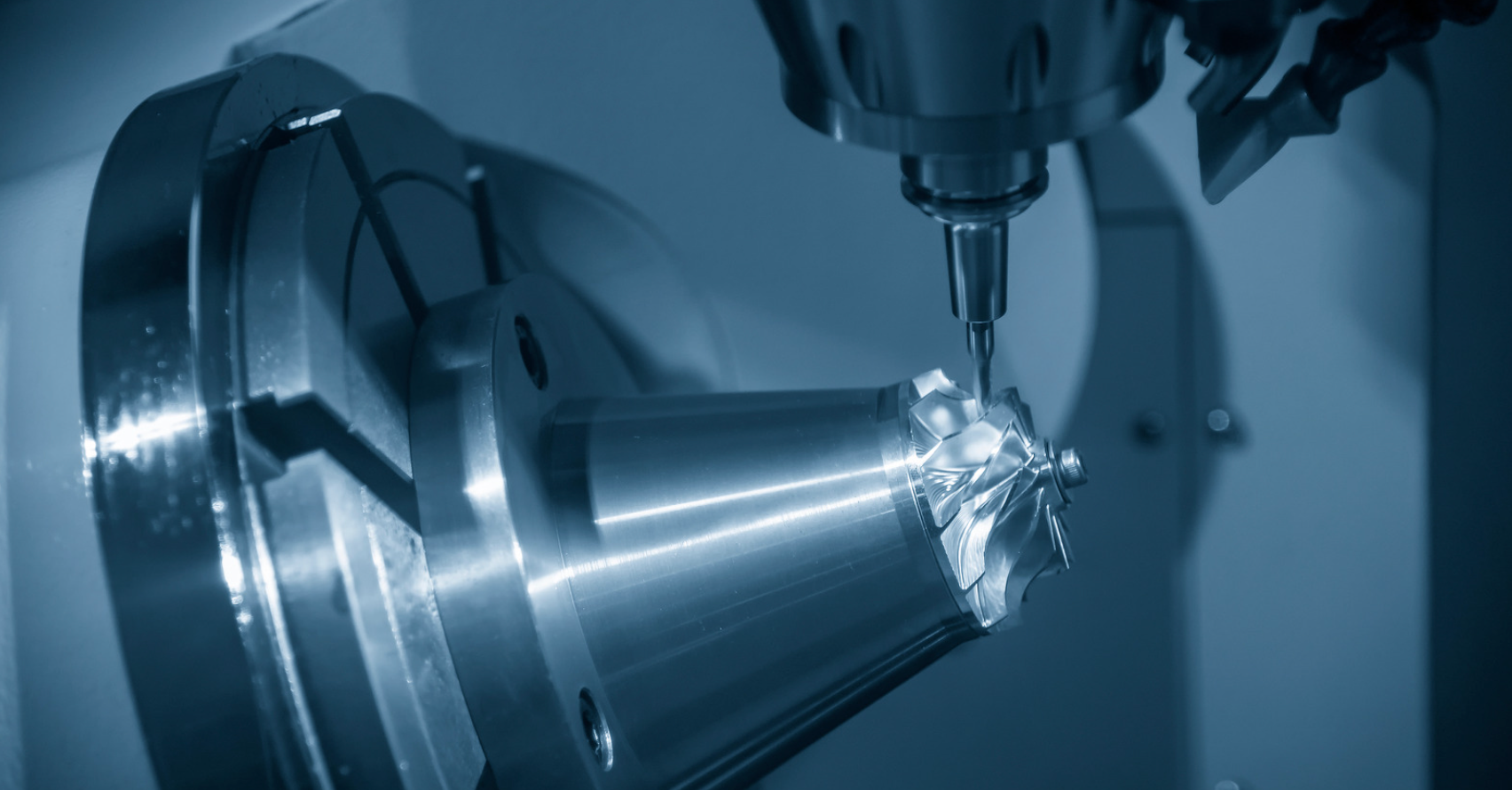

Complex part designs often require multi-axis machining, custom tooling, and additional programming time — all of which increase cost. Deep cavities, thin walls, and intricate features may also slow down machining speeds or require multiple setups.

How Complexity Impacts Cost:

- Increases CAM (Computer-Aided Manufacturing) programming time

- Requires more quality assurance checks

- Demands higher-skilled operators or engineers

Quantity and Production Volume

Economies of scale are a major cost factor. Small batch or prototype runs often carry higher per-unit costs due to setup time and minimal material usage. High-volume orders can significantly reduce the price per part.

Cost Benefits of Volume:

- Tooling and setup amortized over more units

- Automated processes (like bar feeding and palletizing) become viable

- Faster turnaround with reduced idle time

Tolerance and Surface Finish Requirements

Tight tolerances and specialized surface finishes often require slower machining speeds, additional inspection time, and sometimes post-processing steps like grinding or polishing.

Examples:

- Medical implants may require micro-finishes and flawless tolerances

- Aerospace parts often need inspection documentation and compliance with AS9100D

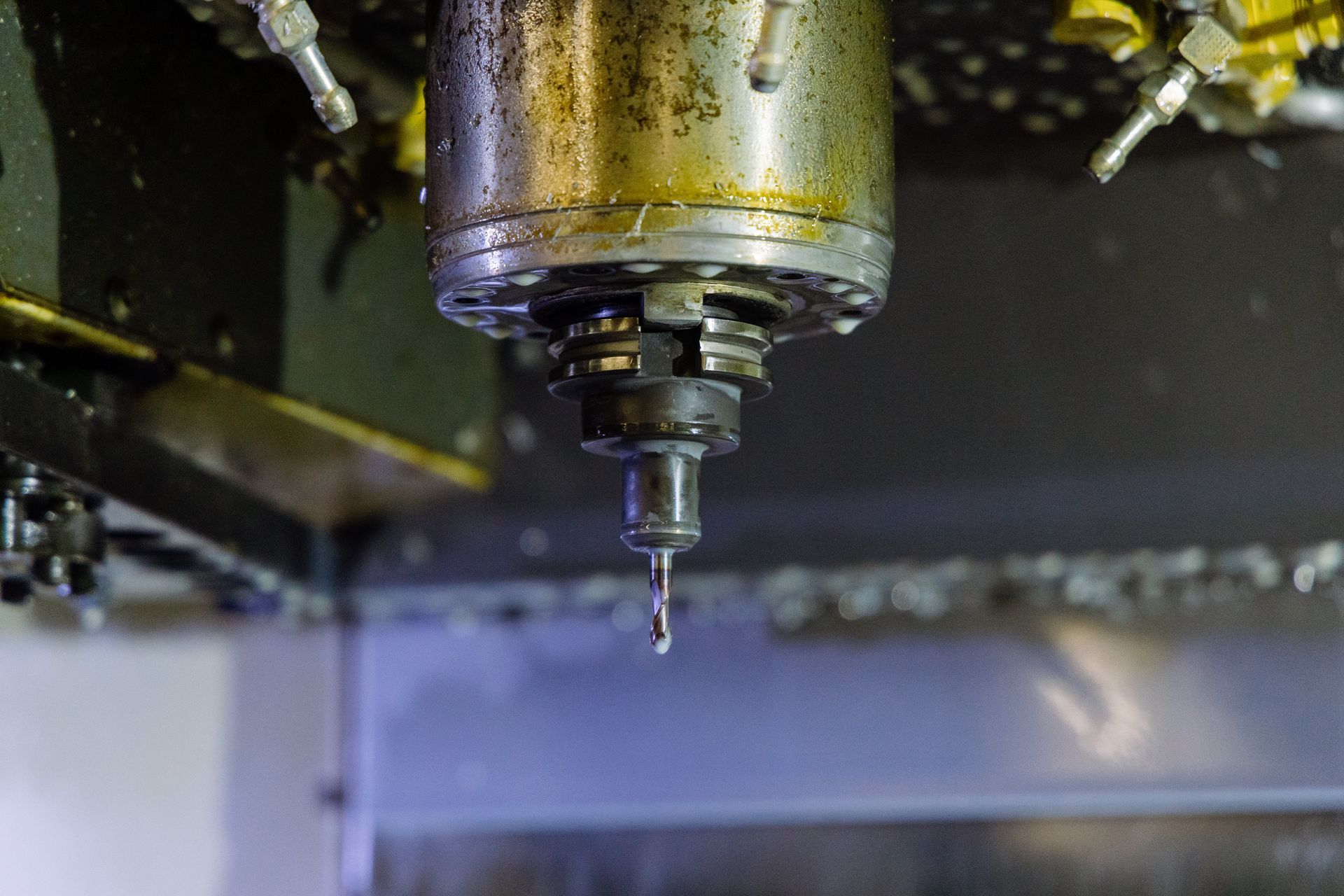

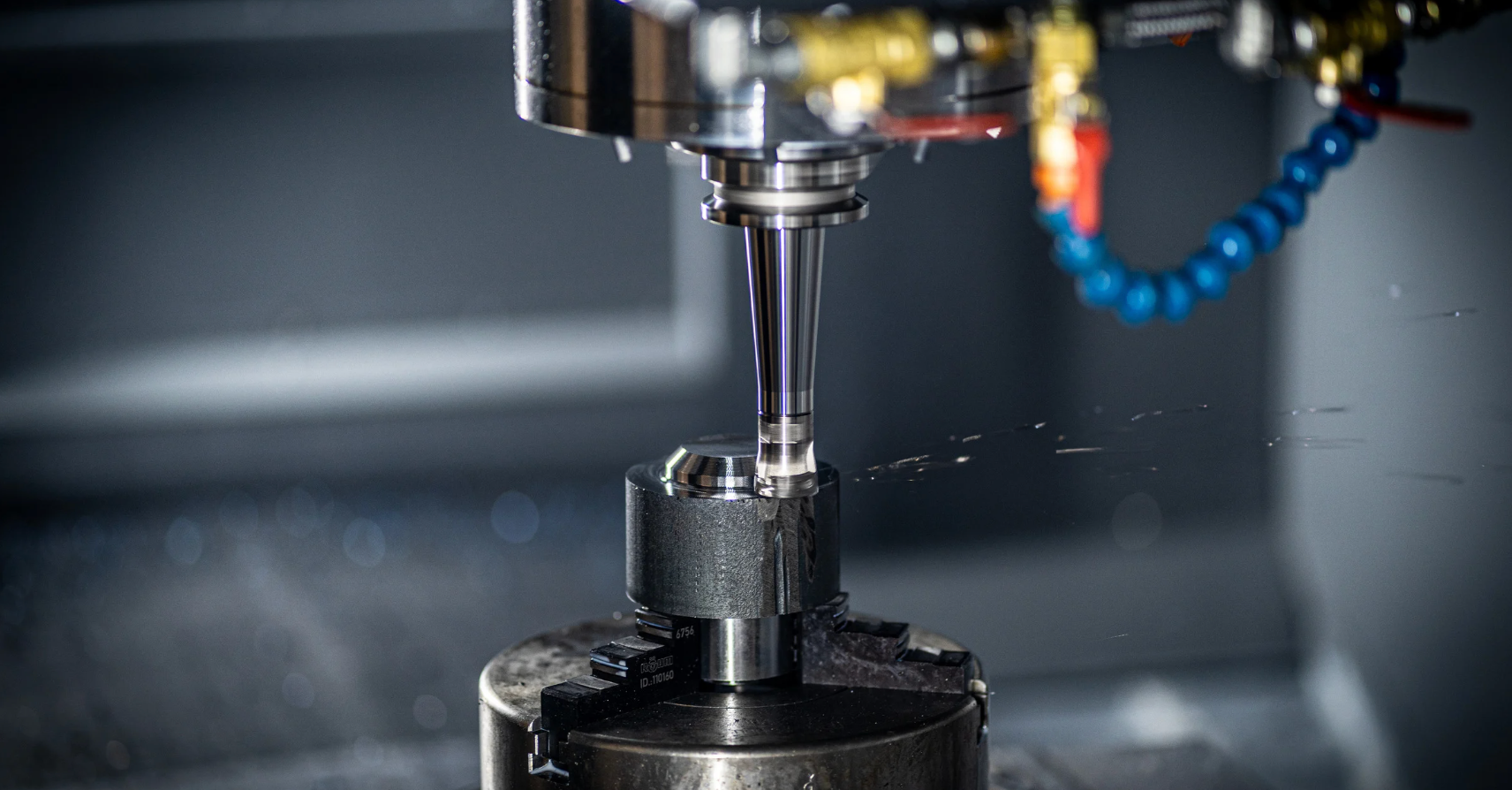

Machining Time and Tooling Wear

The longer a part takes to machine, the higher the labor and equipment costs. Tool changes, feed rates, and machine time all affect final pricing — especially with harder materials or tighter specs.

Cost Factors Involved:

- Number of toolpaths and tool changes

- Machine run-time per part

- Tool wear and replacement frequency

Quality Control and Certifications

At Modelcraft Co., every part is inspected to ensure compliance with strict industry standards. While this adds to the cost, it guarantees performance, reduces failures, and builds trust with critical industries.

Why It Matters:

AS9100D and ISO 9001:2015 certification means thorough inspections

Documented quality control prevents costly rework or field failures

First Article Inspections (FAIs) and PPAPs may be required for regulated sectors

Quality Control and Inspection

While not a machining technique per se, inspection is a critical part of Modelcraft’s CNC workflow. All parts undergo full inspections using advanced metrology equipment. This ensures every component meets customer specs and industry standards like AS9100D and ISO 9001:2015.

Applications:

- Across all sectors — ensuring parts function as designed in mission-critical environments.

Optimize Costs Without Compromising Quality

CNC machining costs are influenced by a combination of engineering, material science, and production efficiency. At Modelcraft Co., we collaborate closely with clients to deliver cost-effective, high-quality parts without compromising precision. By understanding these key factors, you can better manage your budget while achieving outstanding results.

Recent Articles