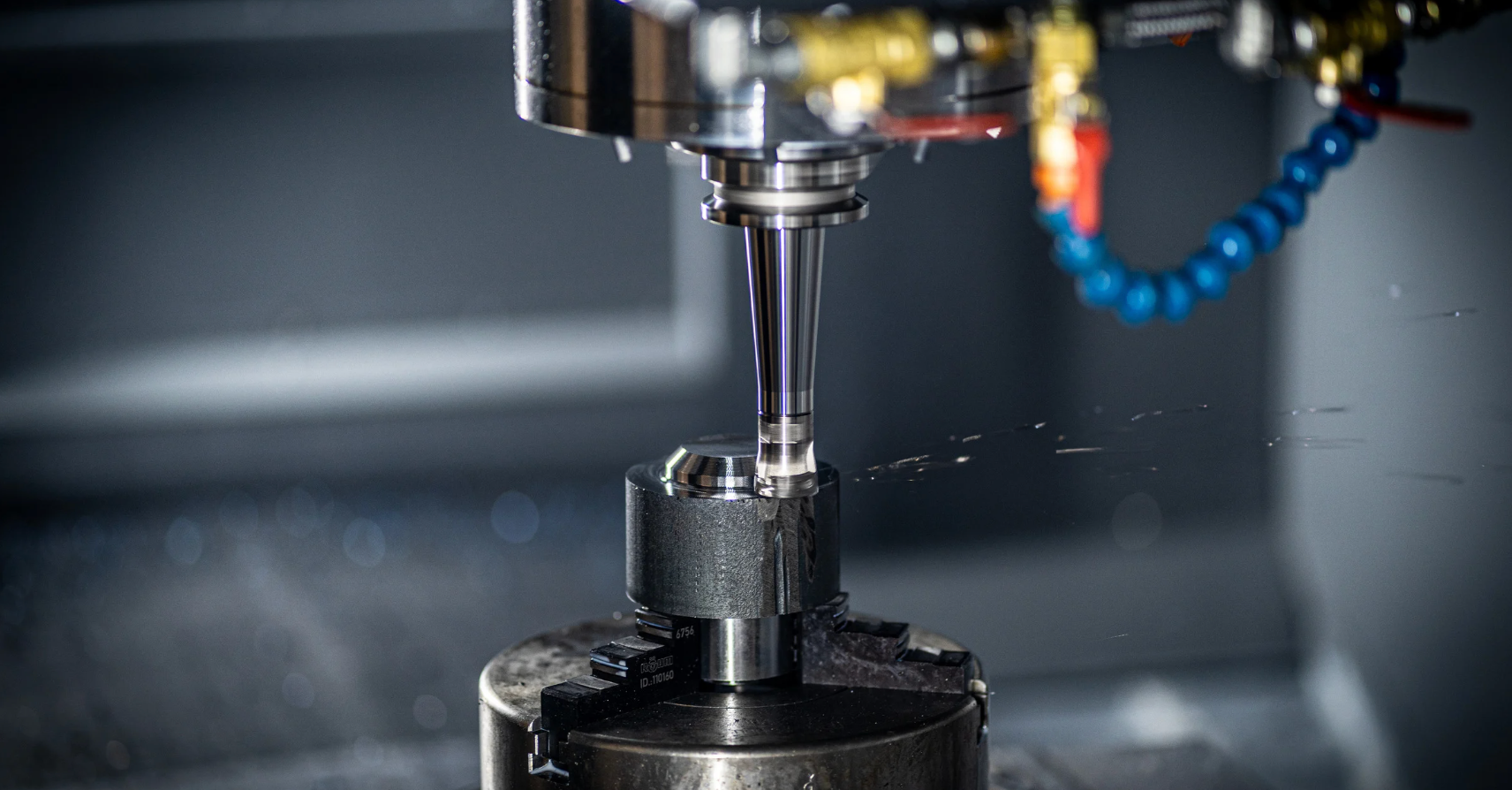

What Are the Best Materials for CNC Machining and Why?

What Are the Best Materials for CNC Machining and Why?

Why Material Choice Matters in CNC Machining

The right material ensures that the final part meets the functional, aesthetic, and performance demands of the application. Whether you need lightweight aerospace brackets or sterile-ready medical tools, each material has unique benefits and trade-offs.

Key Factors to Consider:

- Strength and durability

- Corrosion and chemical resistance

- Machinability and cost

- Tolerance retention

- Industry-specific requirements

Aluminum – Lightweight & Versatile

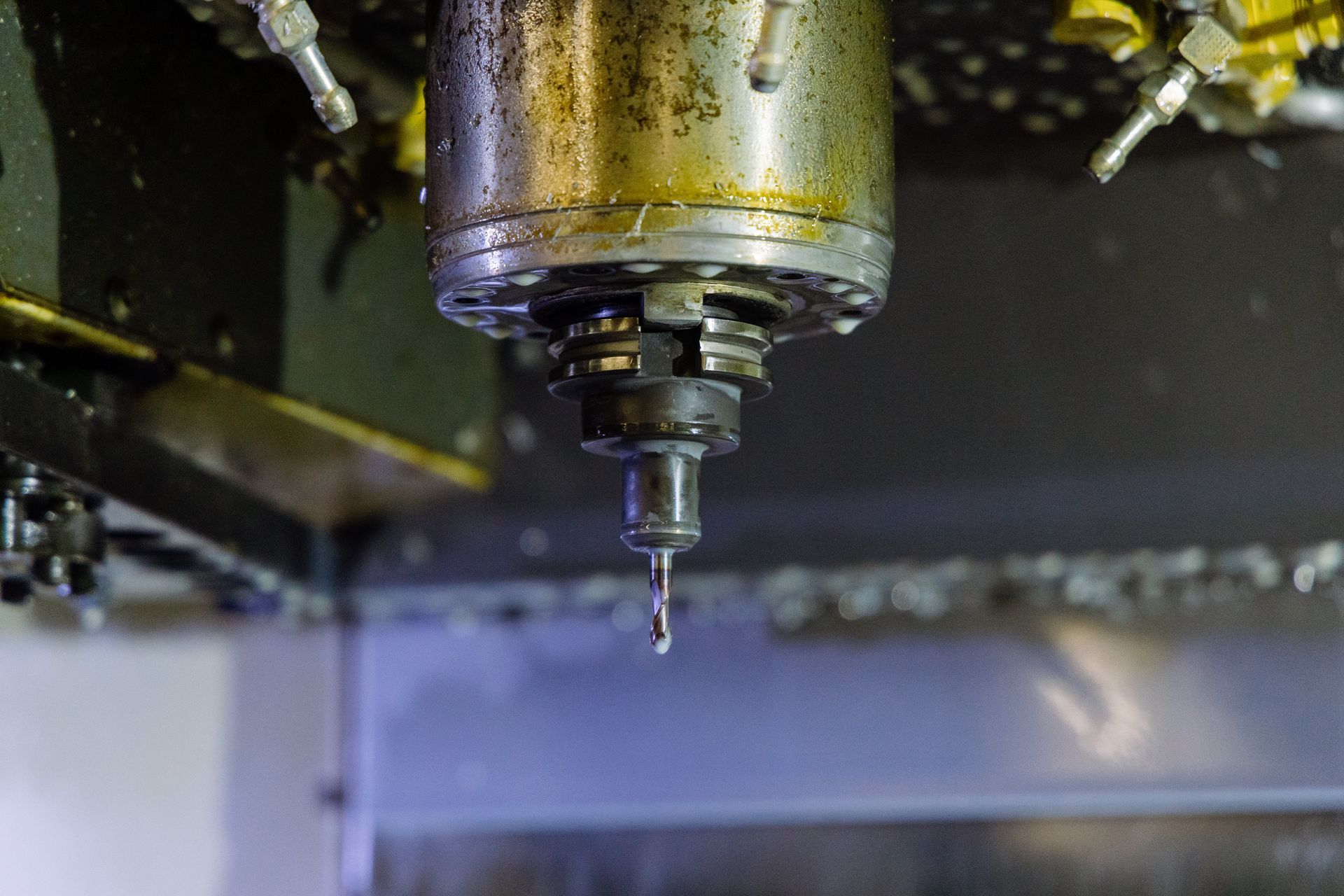

Aluminum is one of the most commonly used materials in CNC machining due to its excellent machinability, corrosion resistance, and high strength-to-weight ratio. It also dissipates heat well, making it ideal for high-speed machining.

Best For:

- Aerospace components

- Consumer electronics

- Commercial enclosures and housings

Popular Grades:

- 6061: General-purpose, easy to machine

- 7075: Stronger, commonly used in aerospace

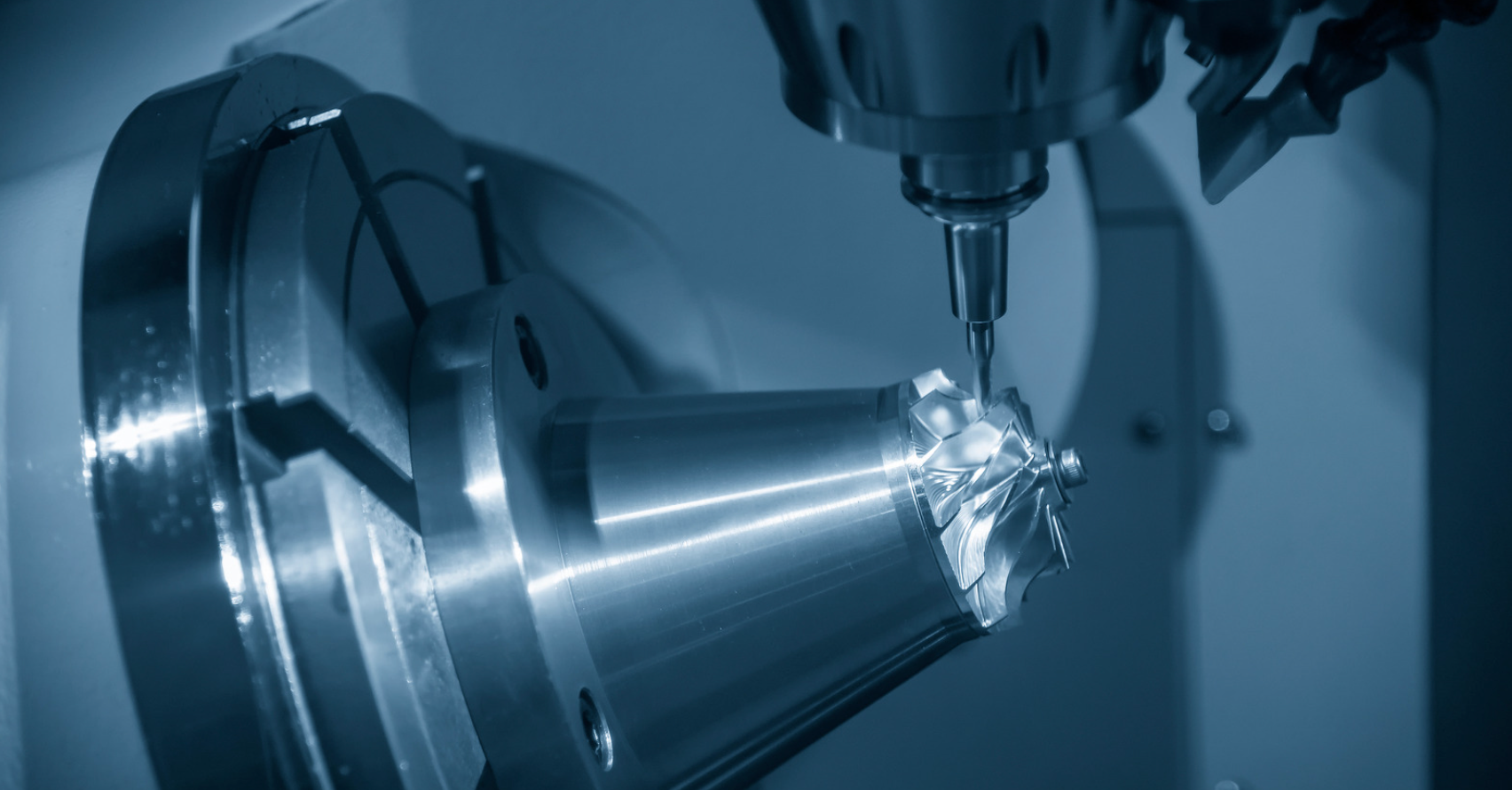

Titanium – High Performance for Critical Applications

Titanium is strong, lightweight, and highly resistant to corrosion, especially from saltwater and bodily fluids. It’s harder to machine, but invaluable for parts that must withstand extreme environments.

Best For:

- Aerospace structural components

- Medical implants

- High-performance automotive parts

Engineering Plastics – Lightweight, Non-Conductive Options

Advanced plastics like PEEK, Delrin (Acetal), and Nylon offer excellent mechanical properties with reduced weight and cost. These materials are often used where metal strength isn’t required but precision and wear resistance are still critical.

Best For:

- Medical instrument components

- Electrical insulation parts

- Custom tooling and jigs

Highlights:

- Delrin: Excellent dimensional stability

- PEEK: High-temperature resistance and chemical inertness

- Nylon: Durable and low-friction

Brass & Copper – For Precision and Conductivity

Brass and copper are soft metals that machine easily and offer excellent electrical and thermal conductivity. They’re also highly corrosion-resistant, making them ideal for specialty applications.

Best For:

- Electrical components

- Plumbing parts

- Decorative hardware

The Right Material Drives the Right Results

At Modelcraft Co., we don’t just machine parts — we help you engineer better outcomes. Selecting the right material is essential for product success, and our team is here to help guide you based on performance, budget, and end-use environment. With deep experience in both metals and engineering plastics, we deliver parts that perform exactly as needed — every time.

Recent Articles