How Precision CNC Machining Meets the Strict Tolerances of Aerospace Parts

In the aerospace industry, there’s no room for error. From the smallest fasteners to complex turbine components, every part must meet exacting standards to ensure safety, performance, and reliability. Precision CNC (Computer Numerical Control) machining plays a critical role in making this possible, enabling manufacturers to produce components with extreme accuracy and consistency. At Modelcraft Co., we’ve spent nearly 60 years delivering precision-machined parts to industries where failure is not an option — and aerospace is one of our specialties. Here’s how CNC precision machining rises to the challenge of meeting the strict tolerances demanded by aerospace applications.

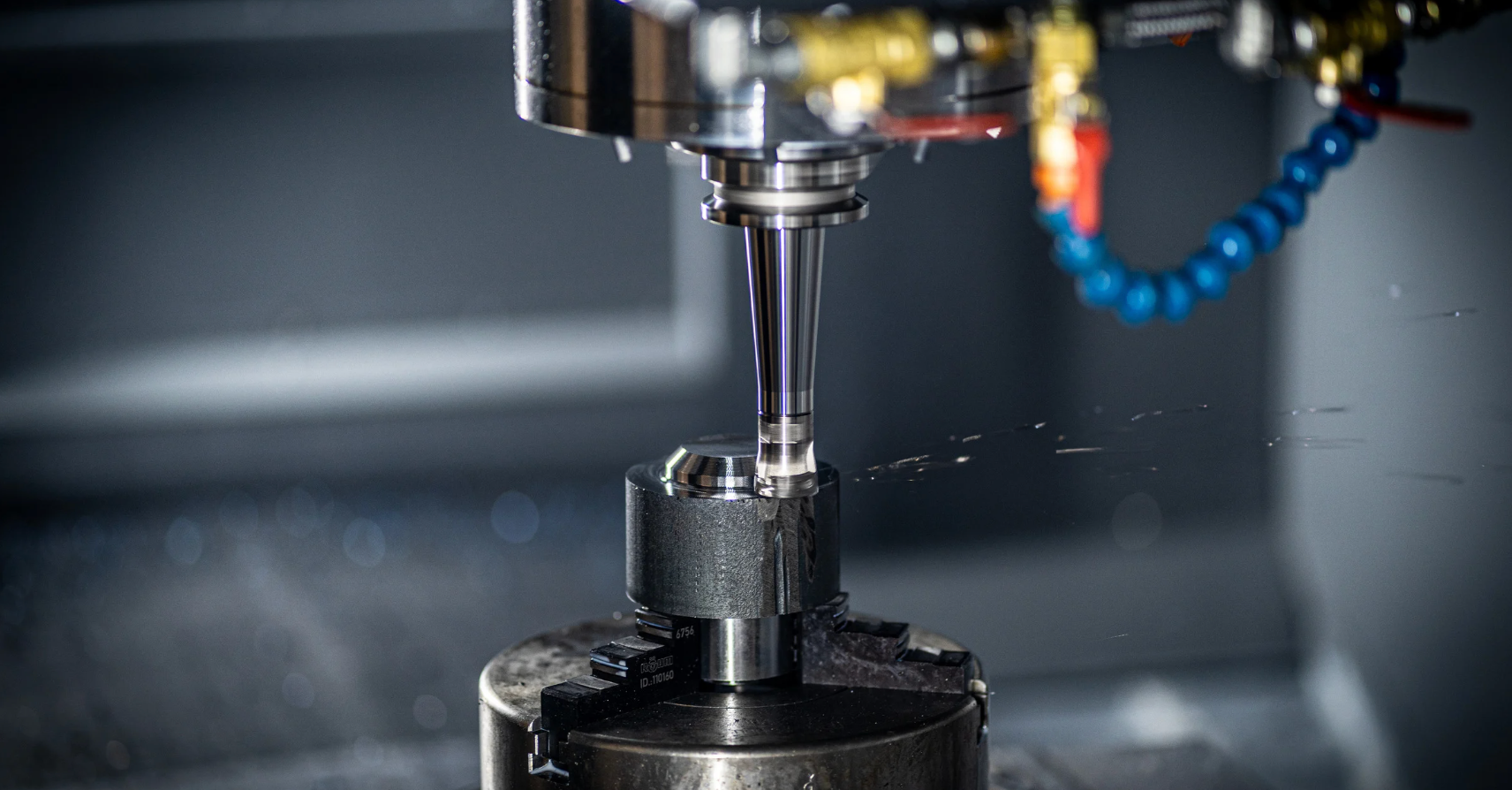

1. Precision at the Micron Level

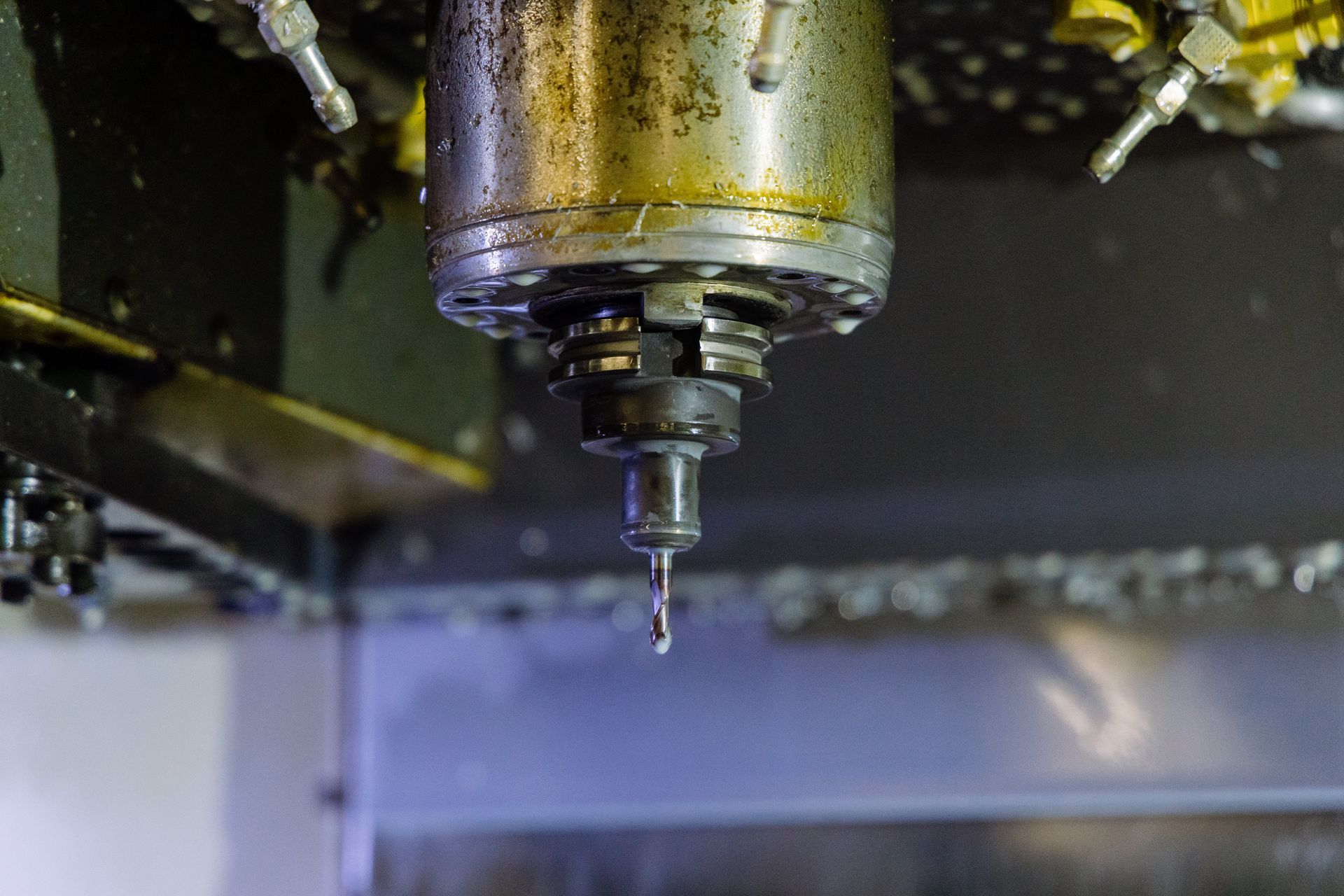

Aerospace parts often require tolerances measured in microns — a fraction of the width of a human hair. CNC machines can achieve this level of precision thanks to advanced controls, feedback systems, and rigid machine structures. By programming exact tool paths and speeds, CNC machining eliminates the variability found in manual processes, ensuring that each part precisely matches its design specifications.

2. Consistency Across Every Production Run

In aerospace, it’s not enough to produce one perfect part — every part in a production run must meet the same stringent standards. CNC machining provides exceptional repeatability, ensuring that whether it’s part number one or part number one thousand, each component meets the exact same tolerances. This consistency is especially important for critical applications like landing gear components, engine parts, and control system elements.

3. Advanced Materials, Expertly Machined

Aerospace components are often made from tough materials like titanium, Inconel, aluminum alloys, and high-strength stainless steels. These materials are chosen for their strength-to-weight ratio and resistance to extreme temperatures — but they’re also notoriously challenging to machine. CNC technology, combined with the expertise of skilled machinists, makes it possible to handle these materials with precision while preserving their mechanical properties.

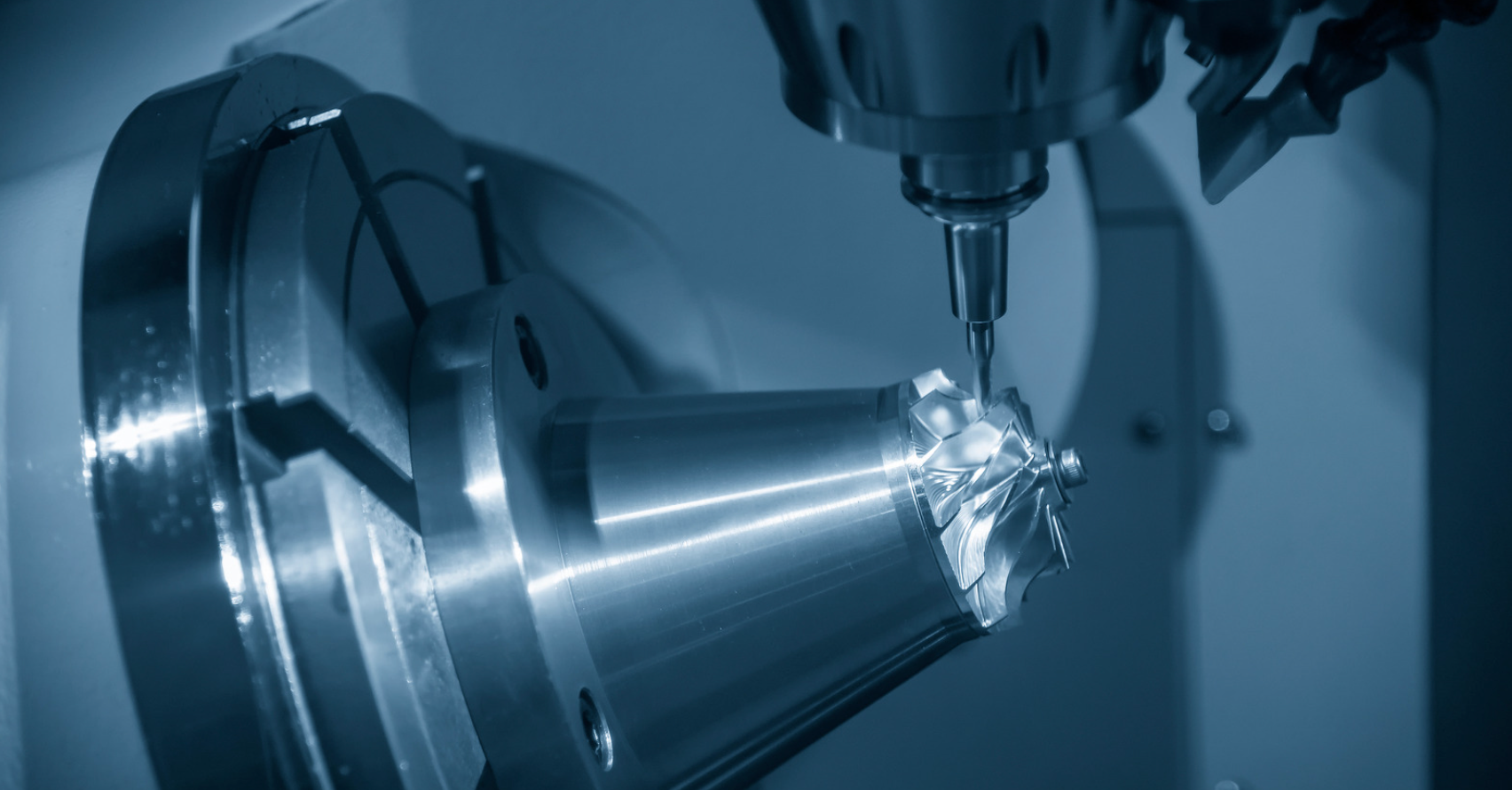

4. Complex Geometries and Tight Deadlines

Modern aerospace designs push the limits of engineering, often requiring parts with intricate geometries, thin walls, and delicate features. CNC precision machining allows manufacturers to meet these demands by using multi-axis machines capable of simultaneous movements, creating complex shapes in a single setup. This reduces handling, speeds up production, and minimizes the risk of error — critical when working under tight aerospace production timelines.

5. Integrated Quality Control

Aerospace manufacturing is governed by rigorous quality standards, including AS9100D certification, which Modelcraft Co. proudly holds. CNC precision machining integrates in-process inspection systems, automated measurements, and full documentation to ensure compliance at every step. This closed-loop approach to quality control guarantees that every part meets or exceeds the required tolerances and industry certifications.

6. Collaboration and Engineering Expertise

Meeting aerospace tolerances isn’t just about machines — it’s about people. At Modelcraft Co., our highly trained and experienced team works closely with aerospace customers to understand their challenges, recommend solutions, and refine part designs for manufacturability. This collaborative approach ensures not only that parts meet tolerance requirements but that they are optimized for cost, performance, and production efficiency.

Precision That Keeps Aerospace Moving Forward

Precision CNC machining is the backbone of aerospace manufacturing, making it possible to achieve the extreme tolerances that keep aircraft flying safely and reliably. At Modelcraft Co., we combine cutting-edge technology, decades of experience, and an unwavering commitment to quality to deliver aerospace components that meet the highest standards. Get in touch with us today to learn more.

Recent Articles