What Are the Most Common CNC Machining Techniques & Their Applications?

What Are the Most Common CNC Machining Techniques & Their Applications?

Understanding CNC Machining

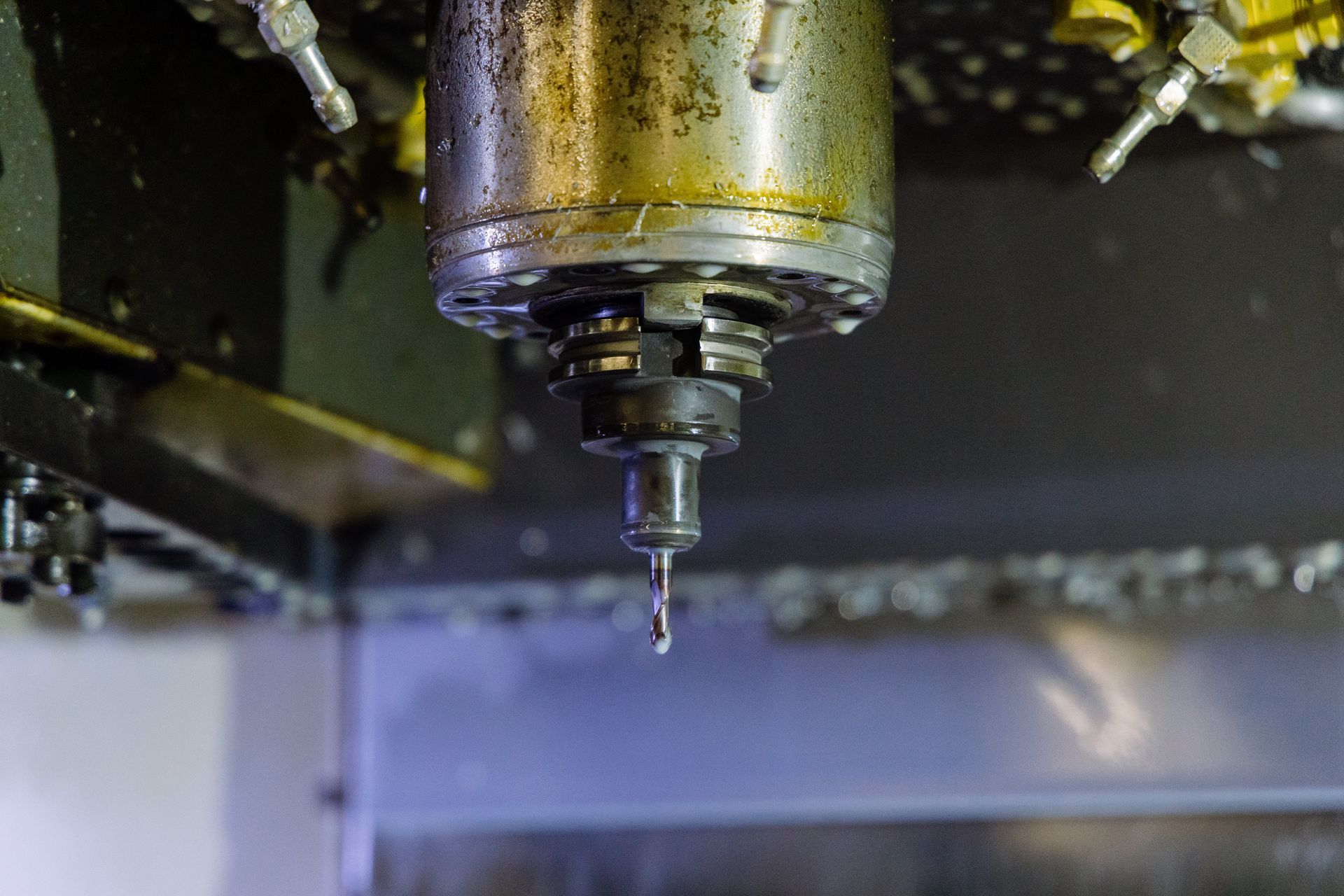

CNC machining is a subtractive manufacturing process that uses computer software to control machine tools. This allows for precise shaping of raw materials like metals and plastics into final components. From simple parts to complex geometries, CNC machining supports consistent and repeatable production — essential for regulated industries that require tight tolerances.

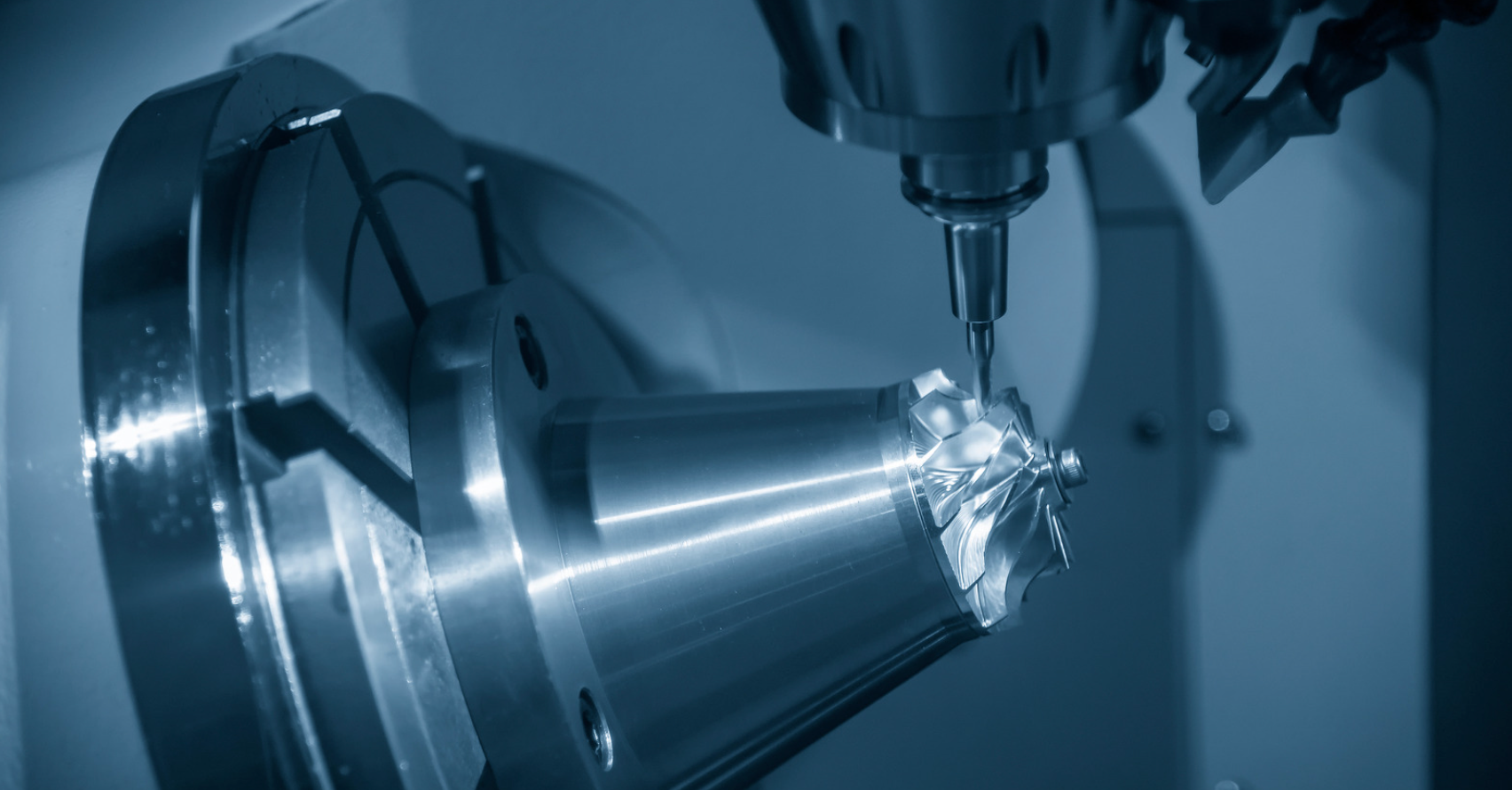

CNC Milling

CNC milling is one of the most common machining processes and involves rotating cutting tools to remove material from a workpiece. Multi-axis milling machines allow for complex and angled geometries, ideal for intricate parts.

Applications:

- Medical Devices: Housings and fixtures for imaging and surgical equipment

- Aerospace: Structural components and brackets

- Commercial: Custom molds, enclosures, and consumer product parts

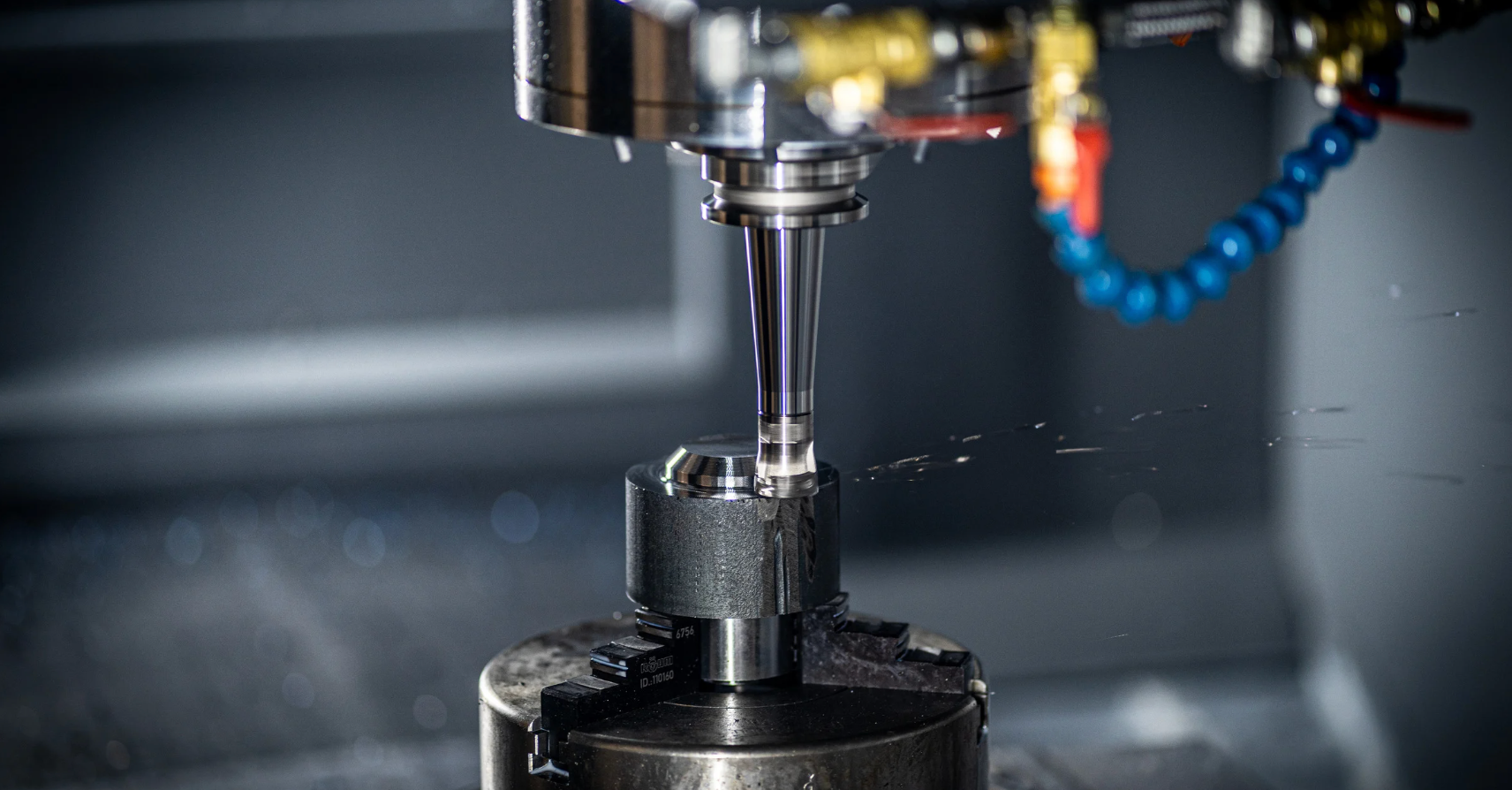

CNC Turning

Turning uses a lathe to rotate the workpiece while a cutting tool removes material. It’s ideal for producing cylindrical or symmetrical parts with high precision.

Applications:

- Medical: Bone screws, implants, and surgical tools

- Aerospace: Shafts, bushings, and fasteners

- Commercial: Connectors, pins, and pulleys

Grinding

CNC grinding involves a rotating abrasive wheel that smooths or shapes the surface of a material. It’s commonly used as a finishing operation for parts that need very tight surface tolerances.

Applications:

- Medical: Fine finishing for surgical tools and implants

- Aerospace: Critical high-tolerance components like turbine blades

- Commercial: Precision tools and dies

Wire EDM (Electrical Discharge Machining)

Wire EDM is a non-contact process that uses a thin, electrically charged wire to cut through metal. It’s perfect for hard metals and intricate cuts without creating mechanical stress on the material.

Applications:

- Medical: Complex contours in surgical instrumentation

- Aerospace: Internal channels and tight-tolerance cuts

- Commercial: Mold components and electronic tooling

Quality Control and Inspection

While not a machining technique per se, inspection is a critical part of Modelcraft’s CNC workflow. All parts undergo full inspections using advanced metrology equipment. This ensures every component meets customer specs and industry standards like AS9100D and ISO 9001:2015.

Applications:

- Across all sectors — ensuring parts function as designed in mission-critical environments.

Your Partner in Precision Manufacturing

At Modelcraft Co., we leverage nearly 60 years of experience and a full suite of CNC technologies to solve our clients’ toughest manufacturing challenges. Whether you're in aerospace, medical, or commercial sectors, our expert team and state-of-the-art equipment ensure you receive precision parts that perform with reliability and consistency.

Recent Articles