What Are Some of the Advantages of CNC vs. Conventional Machining?

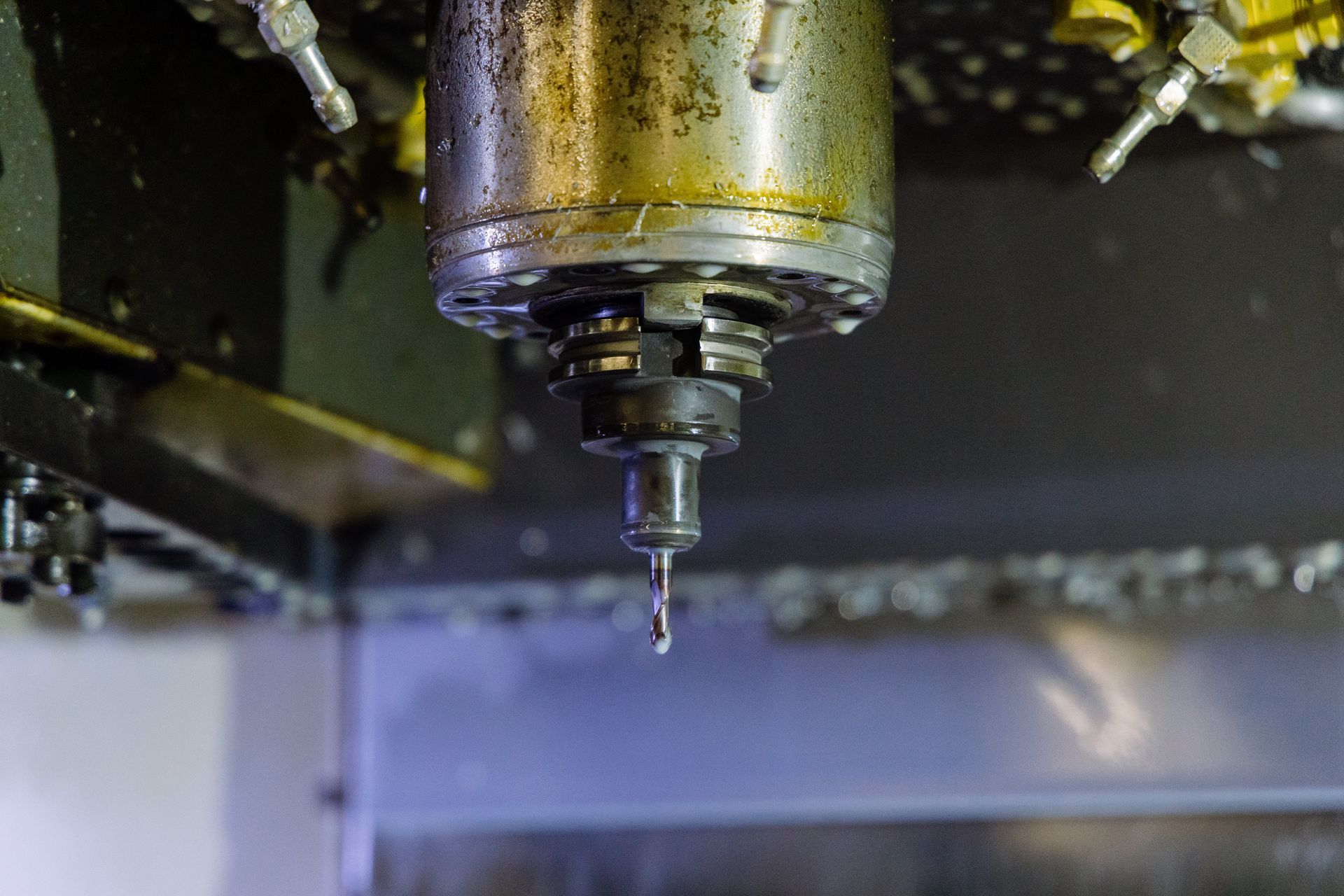

When it comes to manufacturing precision parts, the tools and methods used can make all the difference in quality, speed, and cost-effectiveness. For decades, conventional machining was the industry standard—but with technological advancements, Computer Numerical Control (CNC) machining has rapidly become the preferred approach for many manufacturers, including the team here at Modelcraft Co.

In this blog, we’ll break down some of the biggest advantages CNC machining has over conventional methods, and why more industries are turning to CNC for their complex, high-precision manufacturing needs.

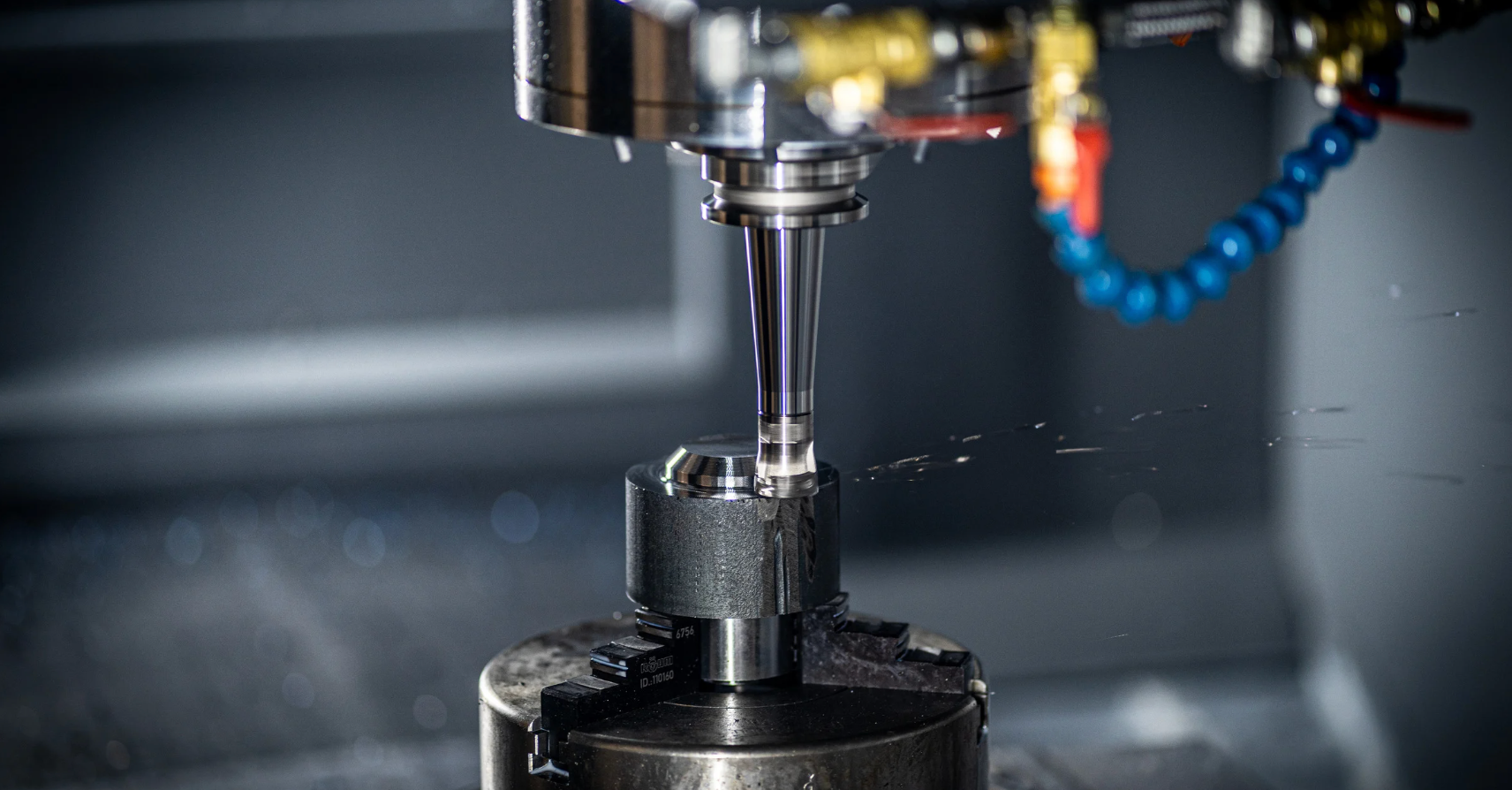

1. Unmatched Precision and Repeatability

CNC machining operates through programmed computer software, eliminating the variability introduced by human handling. This allows for exceptionally tight tolerances—essential for industries like aerospace, medical, and high-tech electronics. At Modelcraft Co., we regularly produce parts that demand sub-micron accuracy, and CNC technology enables us to do that consistently, even across high-volume production runs.

2. Increased Efficiency and Productivity

While conventional machines rely heavily on manual control and operator intervention, CNC machines run autonomously once programmed, often around the clock. This means faster turnaround times, less downtime, and increased output—all without sacrificing quality. Modelcraft Co. leverages CNC equipment to streamline production, reduce lead times, and meet tight delivery schedules without cutting corners.

3. Reduced Human Error

Manual machining is highly dependent on operator skill. While experienced machinists are invaluable, even the best are susceptible to fatigue and mistakes. CNC systems reduce this risk dramatically. With the proper programming and setup, the process is largely hands-off, minimizing the chance of costly errors. This aligns perfectly with Modelcraft Co.’s commitment to quality and reliability, especially for mission-critical components in regulated industries.

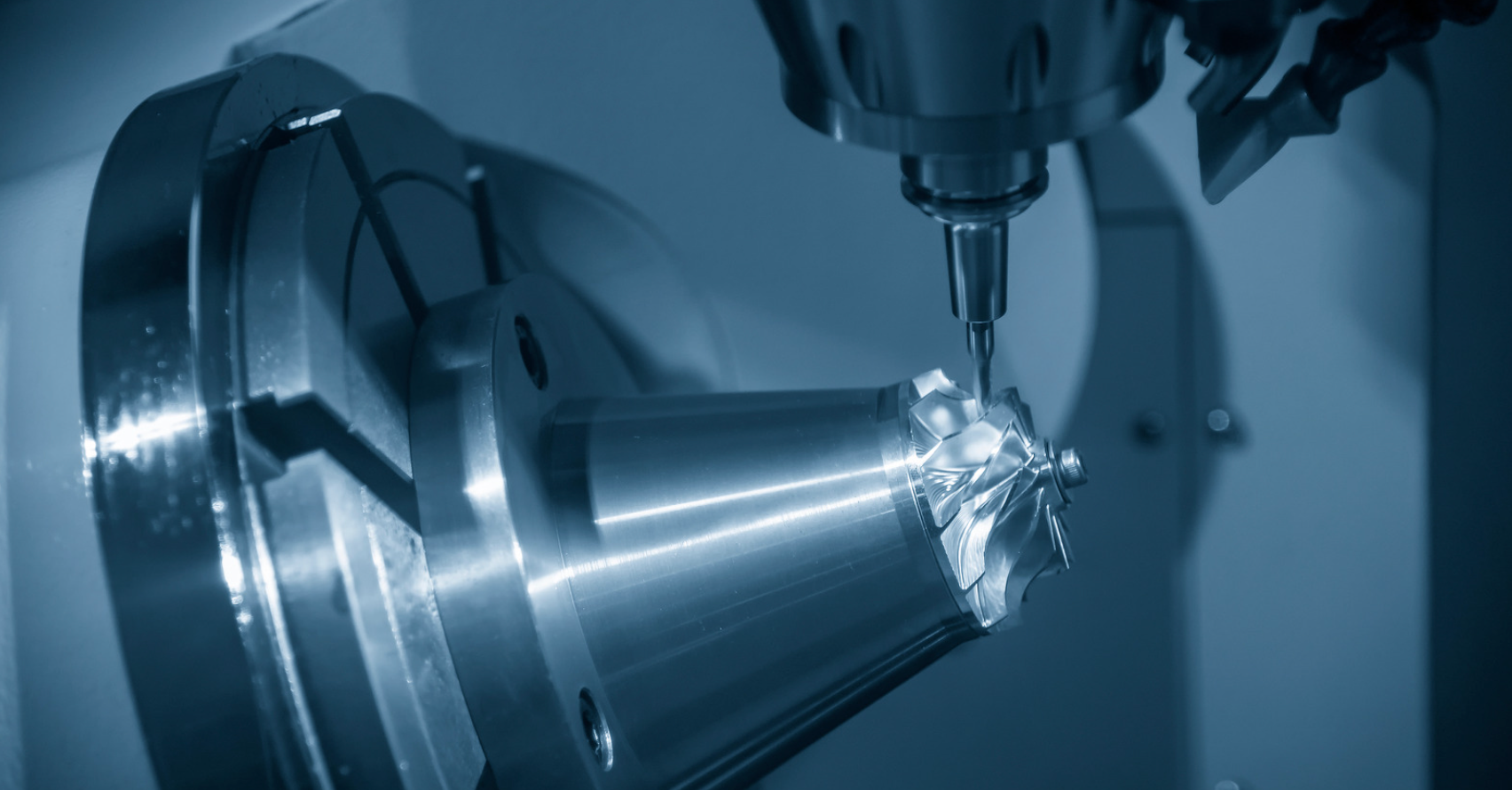

4. Greater Complexity, Less Setup Time

CNC machines are capable of creating highly complex geometries with minimal setup. This is a game-changer when working with intricate part designs or small, high-tolerance components. Conventional machining would require multiple operations and extensive time investment to achieve the same result. At Modelcraft Co., our advanced CNC capabilities allow us to turn even the most demanding part designs into tangible, functional realities.

5. Easy Scalability and Flexibility

Once a CNC machine is programmed for a specific job, scaling from one piece to one thousand is seamless. Program files can be stored, modified, and reused, making repeat orders quicker and more cost-effective. This scalability is essential for manufacturers like Modelcraft Co., where clients often need both rapid prototyping and full production capabilities.

6. Data-Driven Quality Control

CNC machines generate digital data during operation, which can be integrated with quality control systems to ensure compliance with specifications. At Modelcraft Co.., we integrate this data with our full inspection and documentation processes, helping us maintain our AS9100D and ISO 9001:2015 certifications—and giving our clients complete confidence in the parts they receive.

Ready to Upgrade Your Machining Solutions?

Whether you're in aerospace, medical, or commercial manufacturing, the advantages of CNC machining are too valuable to ignore. If you're seeking precision, efficiency, and reliability in your parts production, Modelcraft Co. is ready to help. With nearly 60 years of experience and a dedicated team of experts, we’re here to solve your most complex manufacturing challenges.

Get in touch today to request a quote or learn more about how our CNC machining services can elevate your next project. Call us at (860) 791-3425 or email [email protected].

Recent Articles