How Does CNC Machining Compare to 3D Printing? Which One Should You Choose?

How Does CNC Machining Compare to 3D Printing? Which One Should You Choose?

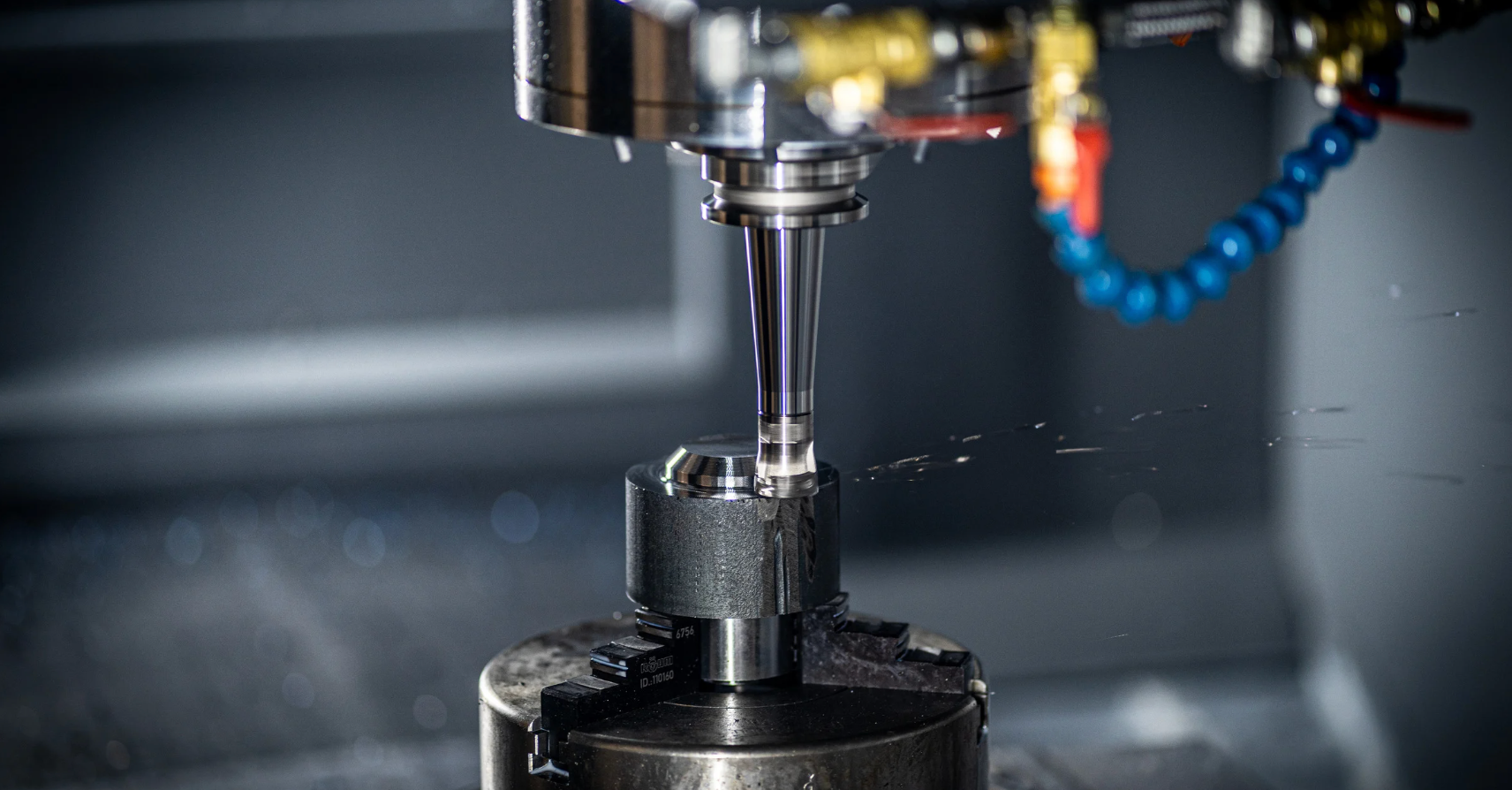

Overview of CNC Machining

CNC (Computer Numerical Control) machining is a subtractive process that removes material from a solid block using cutting tools. It’s known for precision, repeatability, and its ability to handle a wide range of metals and plastics.

Key Strengths:

- Tight tolerances

- High-volume production

- Wide material compatibility (e.g., aluminum, titanium, stainless steel)

Overview of 3D Printing

3D printing (additive manufacturing) builds parts layer-by-layer using materials like thermoplastics, resins, or metal powders. It’s often favored for rapid prototyping and custom or complex geometries.

Key Strengths:

- Rapid design iterations

- Lower startup costs for prototypes

- Excellent for organic shapes and internal channels

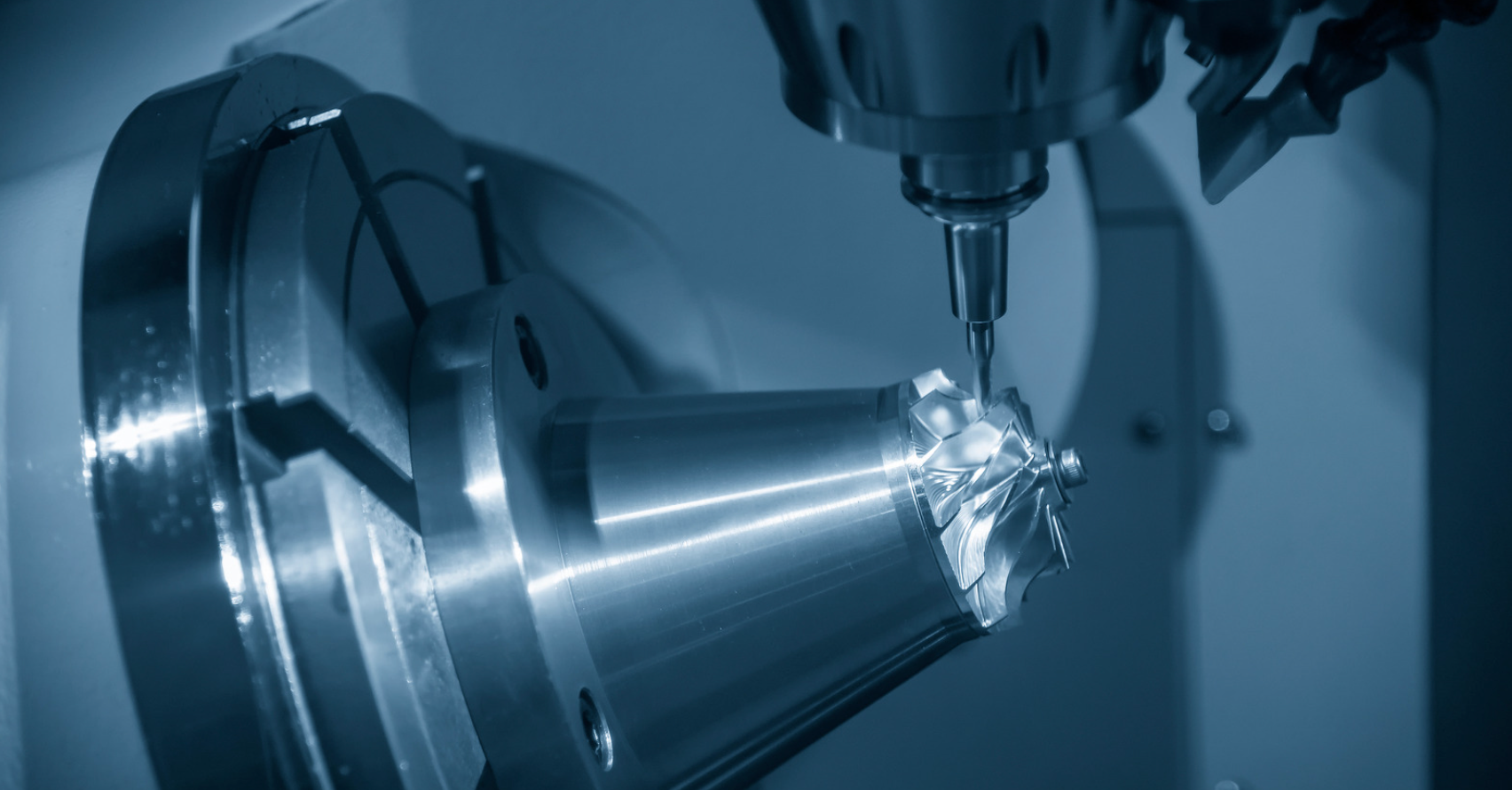

Tolerance and Surface Finish

CNC machining leads the way in terms of tolerance and surface finish. Parts can achieve micron-level accuracy and be polished or ground to mirror-like finishes. 3D-printed parts, by contrast, often require post-processing to match CNC standards.

Comparison:

CNC: Ideal for aerospace and medical components needing exact tolerances

3D Printing: Acceptable for functional prototypes or lower-tolerance needs

Material Options

CNC machining supports a much wider range of production-grade metals and engineering plastics. While 3D printing material science is evolving, it’s still limited compared to traditional methods.

Comparison:

CNC: Aluminum, titanium, Inconel, brass, PEEK, Delrin, etc.

3D Printing: PLA, ABS, nylon, some metal powders (but limited in mechanical strength)

Production Volume and Scalability

When it comes to scaling production, CNC machining is more cost-effective over high volumes. 3D printing can be slower and more expensive per unit when scaling up.

Best Use Cases:

CNC: Mid-to-high volume production, regulated industries

3D Printing: Prototyping, small-batch custom parts, iterative design

Cost and Lead Time

3D printing generally has a lower entry cost for prototypes, especially when tooling or fixturing isn’t needed. CNC machining, while requiring more setup, becomes more economical for higher volumes and repeat jobs.

Typical Cost Factors:

- CNC: Setup time, material waste, tool wear

- 3D Printing: Print speed, material limitations, post-processing

Which One Should You Choose?

If you need high-precision parts, tighter tolerances, and production scalability — CNC machining is the clear winner. That’s why Modelcraft Co. continues to serve the aerospace, medical, and commercial sectors with expert machining services. On the other hand, 3D printing shines during the early stages of development and for quick, flexible prototyping.

Recent Articles