Getting More Out of Your Lathes Through Automation and Live Tooling

In today’s fast-paced manufacturing world, efficiency and precision are more important than ever. To stay competitive, many manufacturers are turning to automation and live tooling to get more out of their lathe operations. At Modelcraft, we’ve implemented these technologies to improve both productivity and quality, and we’re here to share how they can benefit your business too.

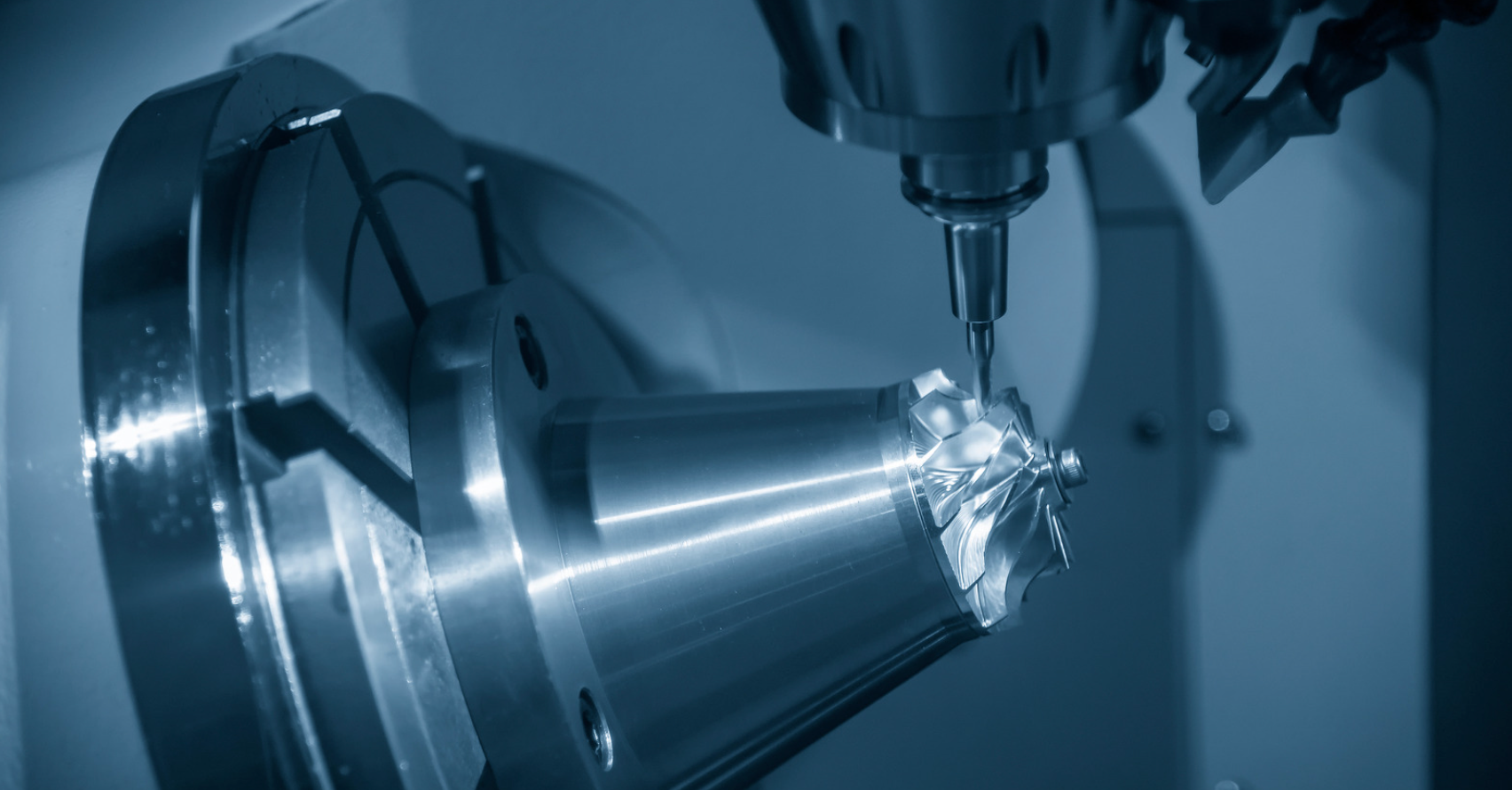

What is Live Tooling?

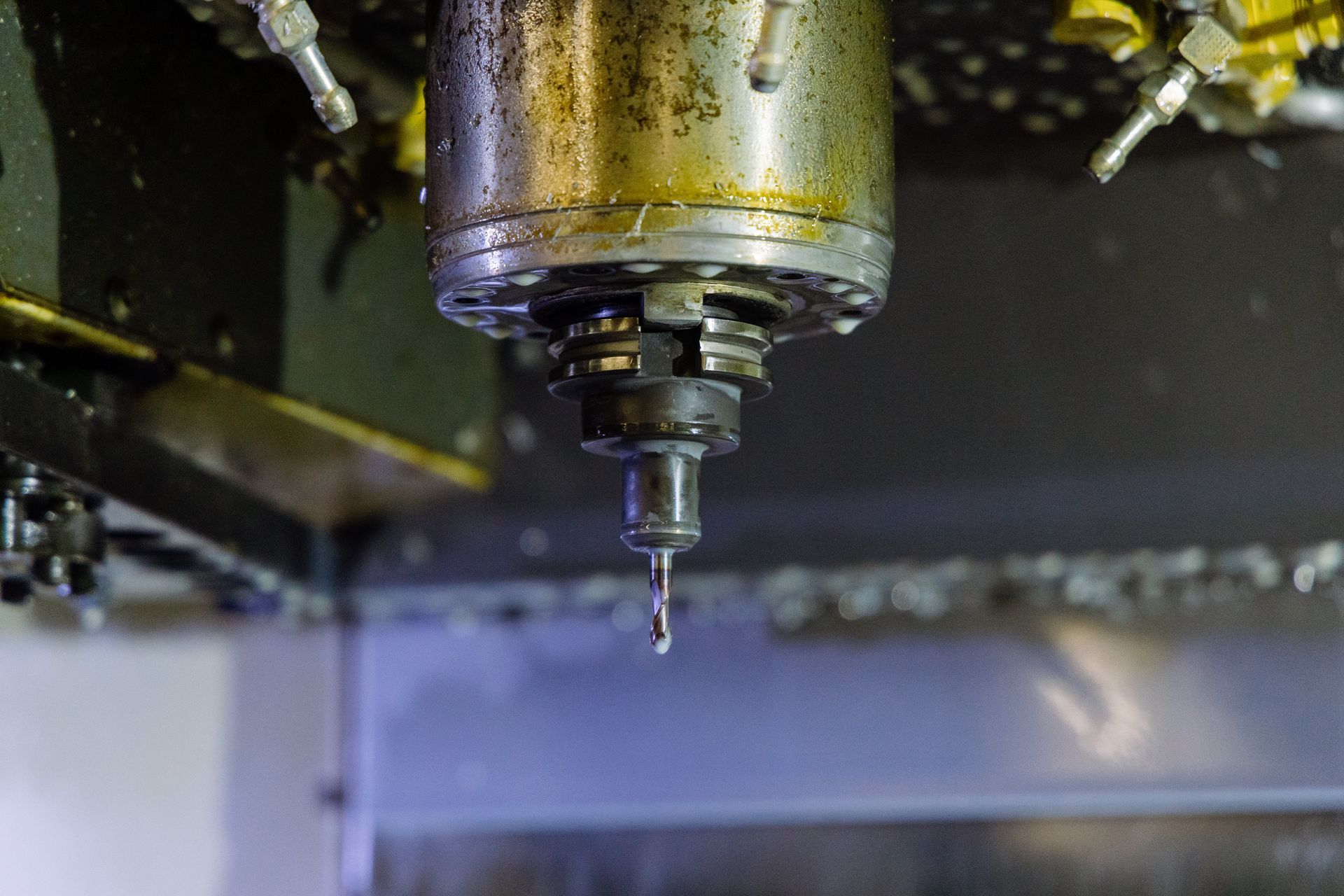

Live tooling allows a lathe to perform additional operations like milling, drilling, and tapping while the part remains in the chuck. This eliminates the need for secondary setups, saving time and reducing the chance for errors. By machining parts in a single setup, manufacturers can streamline their workflow and improve overall precision.

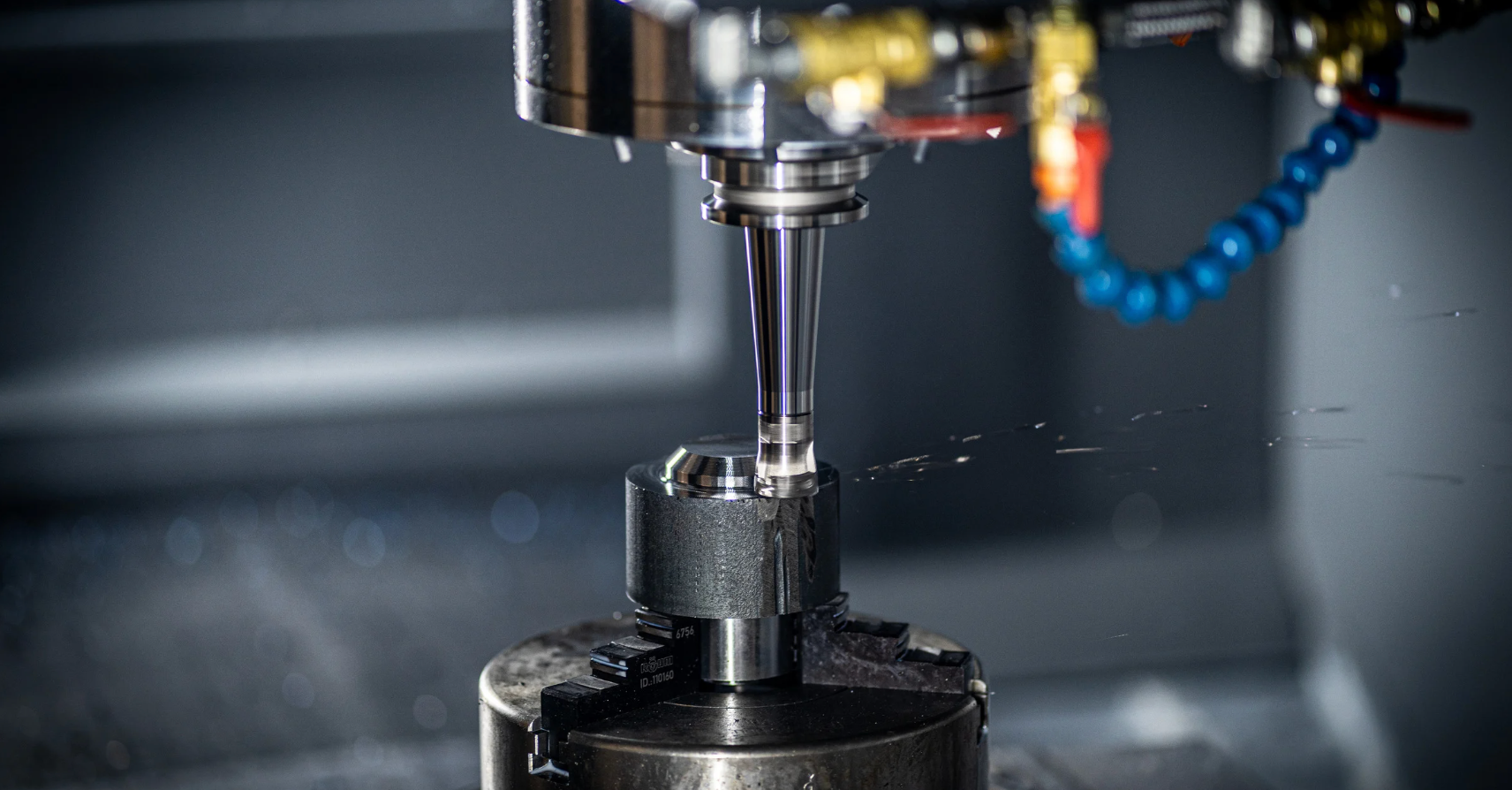

The Role of Automation in Lathe Machining

Automation takes things a step further by allowing machines to run continuously with minimal human intervention. This means higher productivity, consistent quality, and reduced labor costs. Automated lathes can work around the clock, offering manufacturers a way to increase throughput and meet tight deadlines.

Combining Automation and Live Tooling

The combination of automation and live tooling creates a highly efficient system. Automation ensures continuous operation, while live tooling enables multiple operations in one setup. This reduces cycle times, eliminates bottlenecks, and increases the range of parts that can be produced efficiently.

How Modelcraft Leverages These Technologies

At Modelcraft Co., we utilize both automation and live tooling to produce high-precision components for the medical, aerospace, and commercial industries. Our investments in these technologies allow us to meet the tight tolerances and high standards our customers expect while reducing production time and cost.

Optimize With Us At Modelcraft Co.

By incorporating automation and live tooling into your lathe operations, you can increase productivity, reduce costs, and improve the quality of your parts. If you’re looking to optimize your production process, contact Modelcraft today to learn how we can help you achieve these goals.

Recent Articles