The Evolution of Precision Machining: From Handcraft to High-Tech

For nearly 60 years, Modelcraft Co. has been at the forefront of precision machining, adapting to industry advancements while maintaining our commitment to quality craftsmanship. The manufacturing world has evolved significantly, transitioning from manual, hand-crafted techniques to state-of-the-art, high-tech automation. This evolution has not only improved efficiency and accuracy but has also expanded the possibilities of what can be achieved in the medical, aerospace, and commercial industries.

The Handcraft Era: Where It All Began

Before the rise of computer-controlled machines, precision machining was a labor-intensive craft. Skilled machinists relied on manual lathes, mills, and grinders to shape metal parts with meticulous attention to detail. These parts were often produced individually or in small batches, requiring significant time and expertise.

In the mid-20th century, as industries grew and technology progressed, the demand for more complex and precise components increased. This shift marked the beginning of automation in machining, setting the stage for groundbreaking advancements.

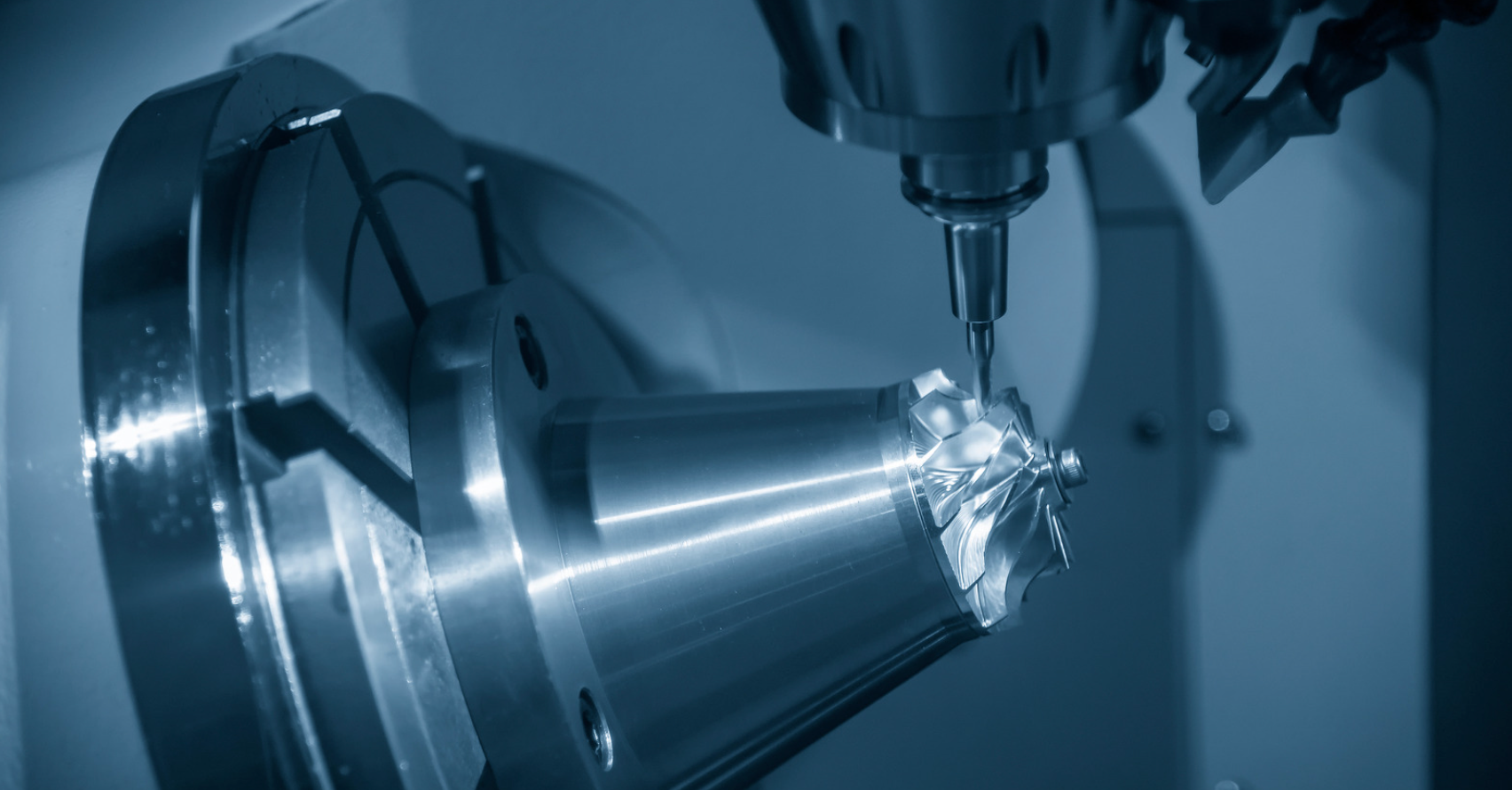

The Introduction of CNC Machining: A Game Changer

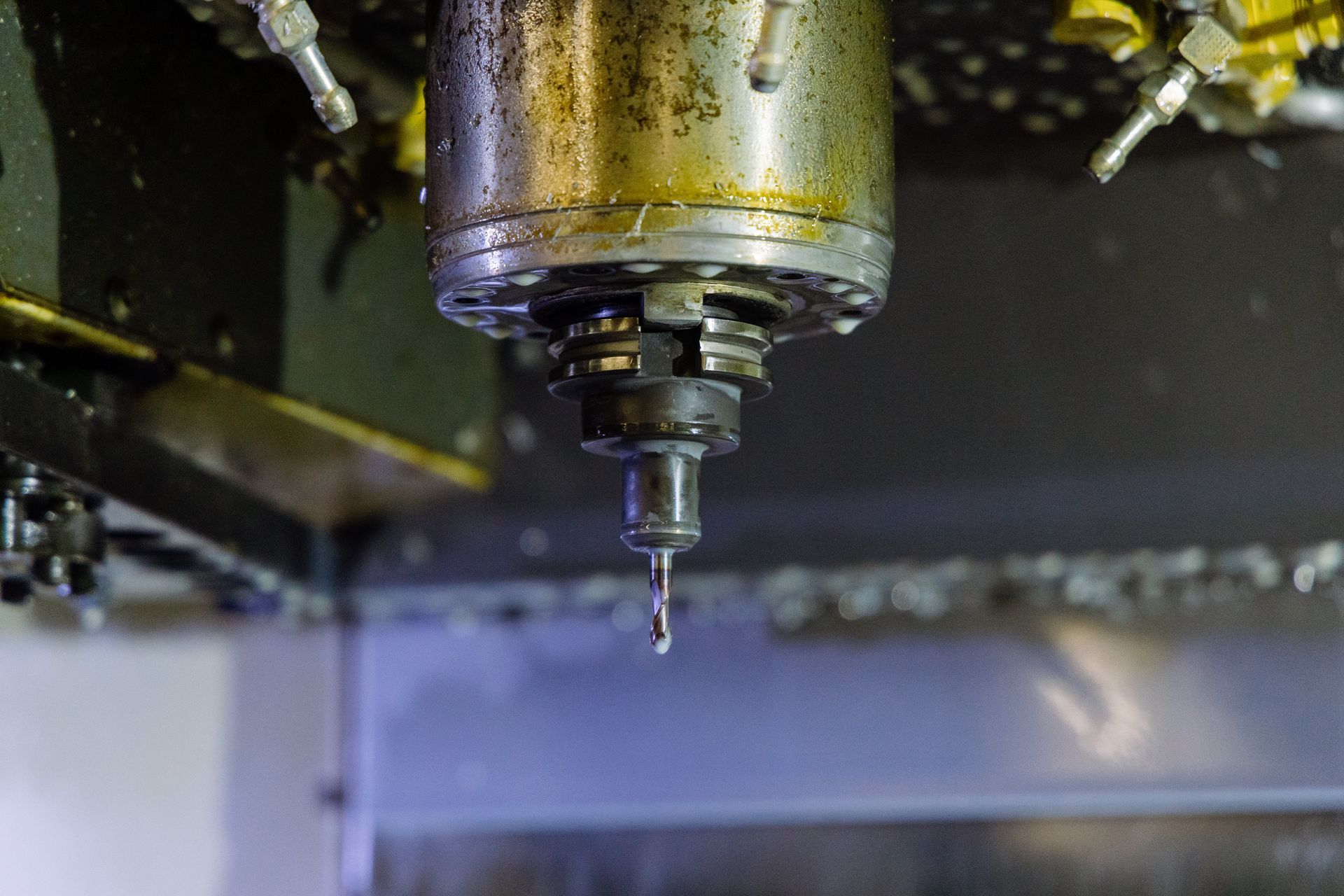

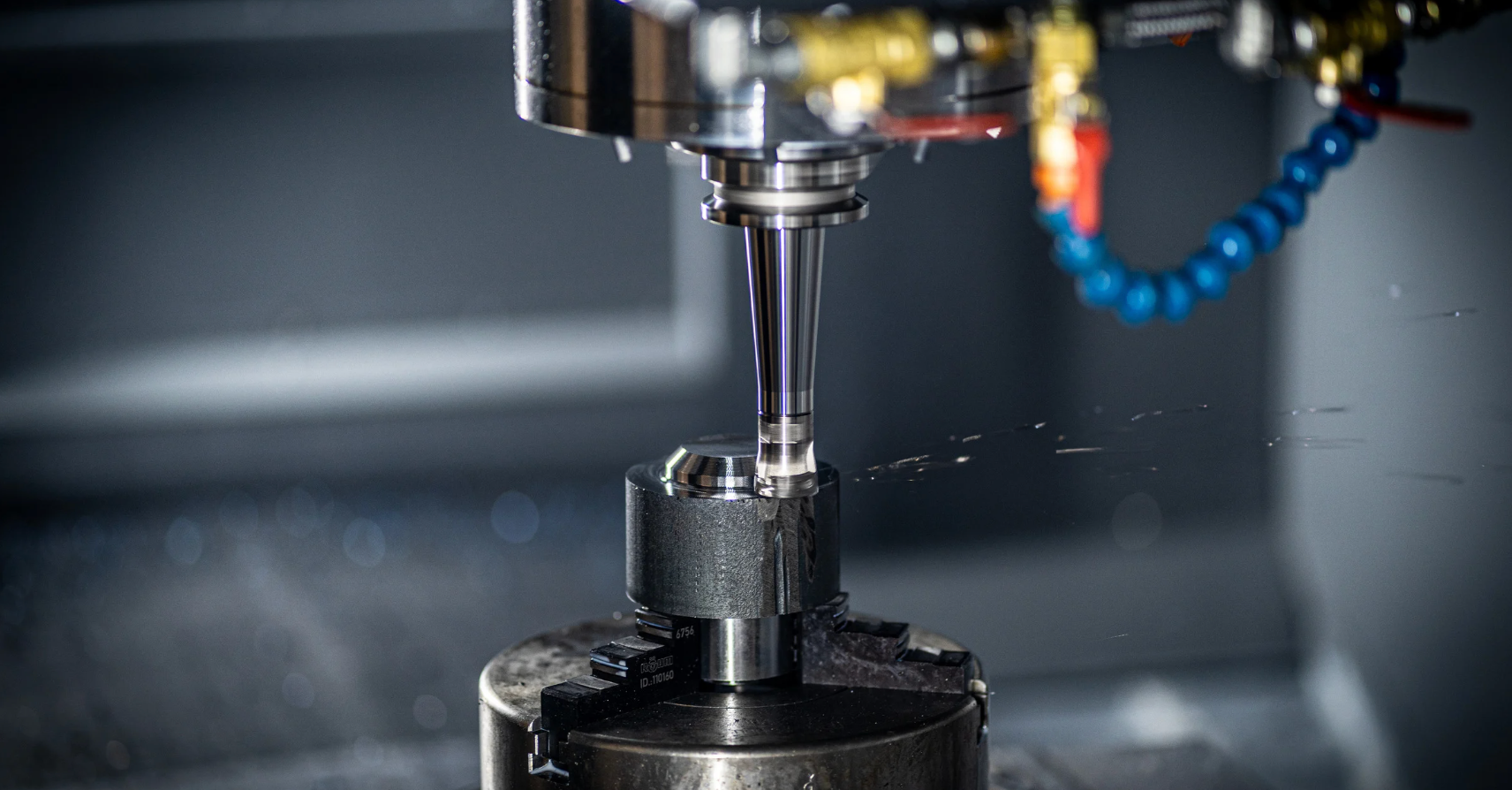

The introduction of Computer Numerical Control (CNC) machining in the 1950s and 1960s revolutionized the industry. Unlike manual machines, CNC technology allowed for parts to be produced with higher precision, repeatability, and efficiency. With the ability to program machine movements using software, manufacturers could create intricate designs and achieve tolerances that were previously unattainable.

At Modelcraft, we embraced CNC technology early on, recognizing its potential to improve consistency and reduce lead times for our customers. Today, our facility is equipped with state-of-the-art CNC milling, turning, and grinding machines, enabling us to produce high-quality components at scale.

The Rise of Advanced Materials & High-Precision Manufacturing

As industries like aerospace and medical devices grew, the demand for stronger, lighter, and more durable materials increased. Precision machining had to evolve to handle advanced alloys, titanium, and medical-grade materials while maintaining tight tolerances.

This required not only better tooling and machine capabilities but also enhanced inspection and quality control processes. At Modelcraft, we ensure every part meets the strictest industry standards, which is why we are AS9100D and ISO 9001:2015 certified. Our quality assurance measures guarantee that the components we manufacture perform reliably in mission-critical applications.

Industry 4.0 & the Future of Precision Machining

We are now in the era of Industry 4.0, where digital technology, automation, and smart manufacturing are reshaping the industry. Innovations such as:

- 5-axis machining – allowing for complex geometries in fewer setups

- Wire EDM (Electrical Discharge Machining) – achieving extreme precision for delicate components

- Robotics & automation – increasing efficiency and reducing human error

- AI & machine learning – optimizing production processes and predictive maintenance

At Modelcraft, we continuously invest in cutting-edge technology to stay ahead of these trends. Our commitment to innovation ensures we can meet the evolving needs of our customers and deliver better products through manufacturing innovation.

From Past to Future: Modelcraft’s Commitment to Excellence

The journey from handcrafted machining to high-tech automation has been remarkable, and Modelcraft Co. has been part of this transformation every step of the way. With nearly six decades of expertise, we take pride in helping customers solve their most challenging manufacturing needs through precision machining, advanced technology, and unwavering quality. As we look to the future, our mission remains the same: to enable our customers' success by delivering the highest-quality machined components with precision, efficiency, and reliability.

Need a precision machining partner who stays ahead of industry advancements? Contact Modelcraft today.

Recent Articles