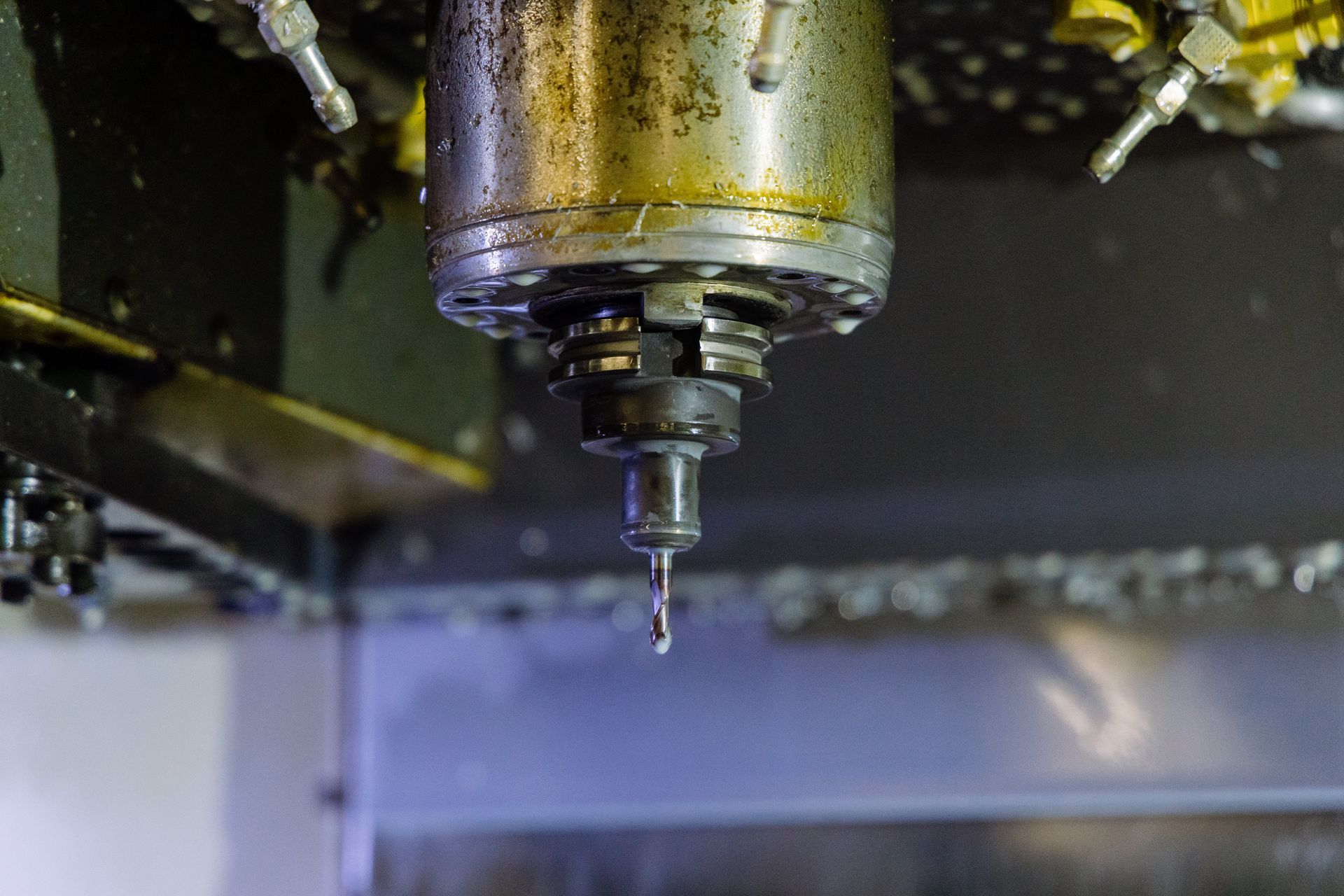

CONNSTEP & Modelcraft Co: Continuous Improvement Measures Reduce Set-Up & Inspection Time

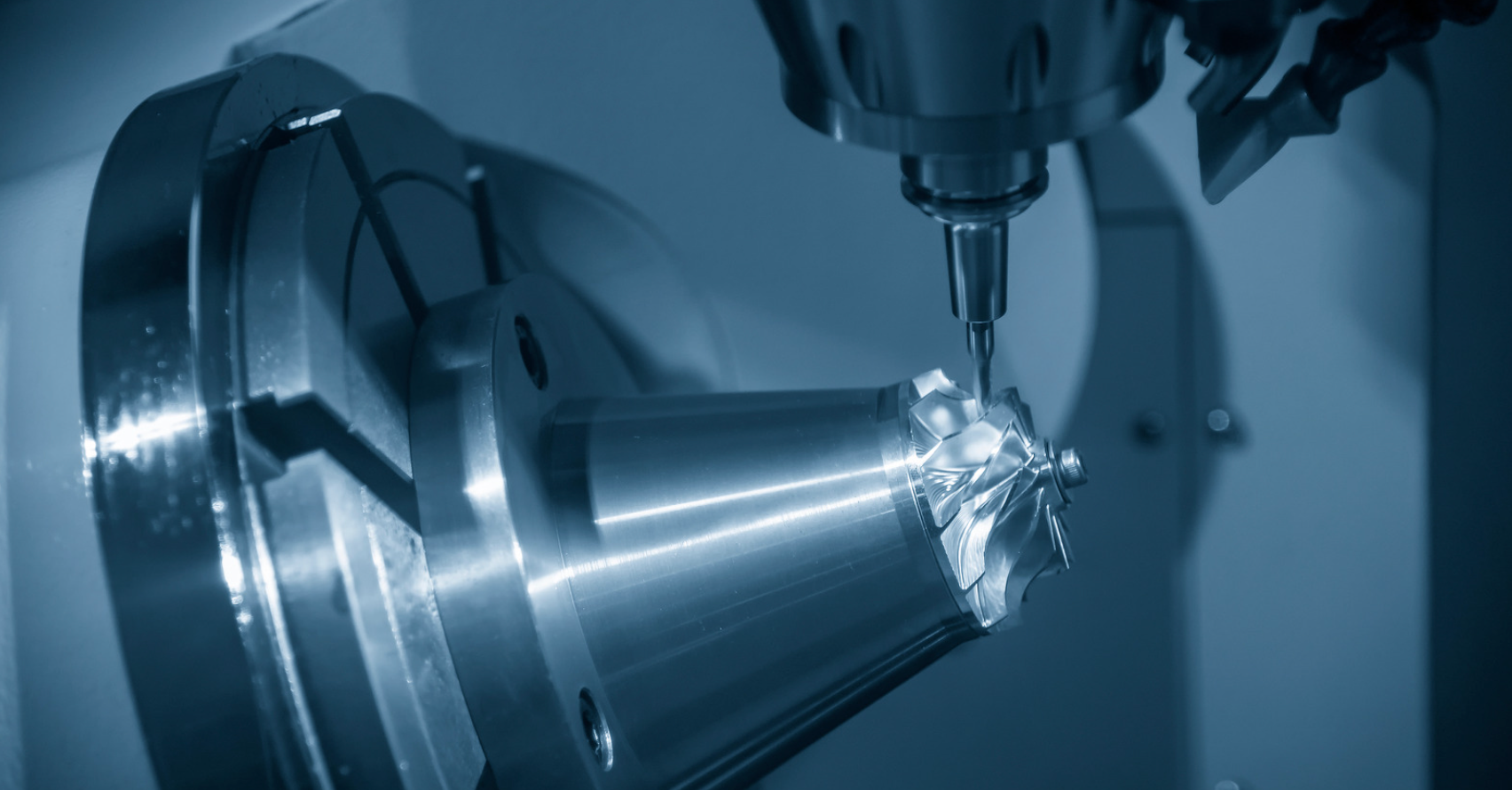

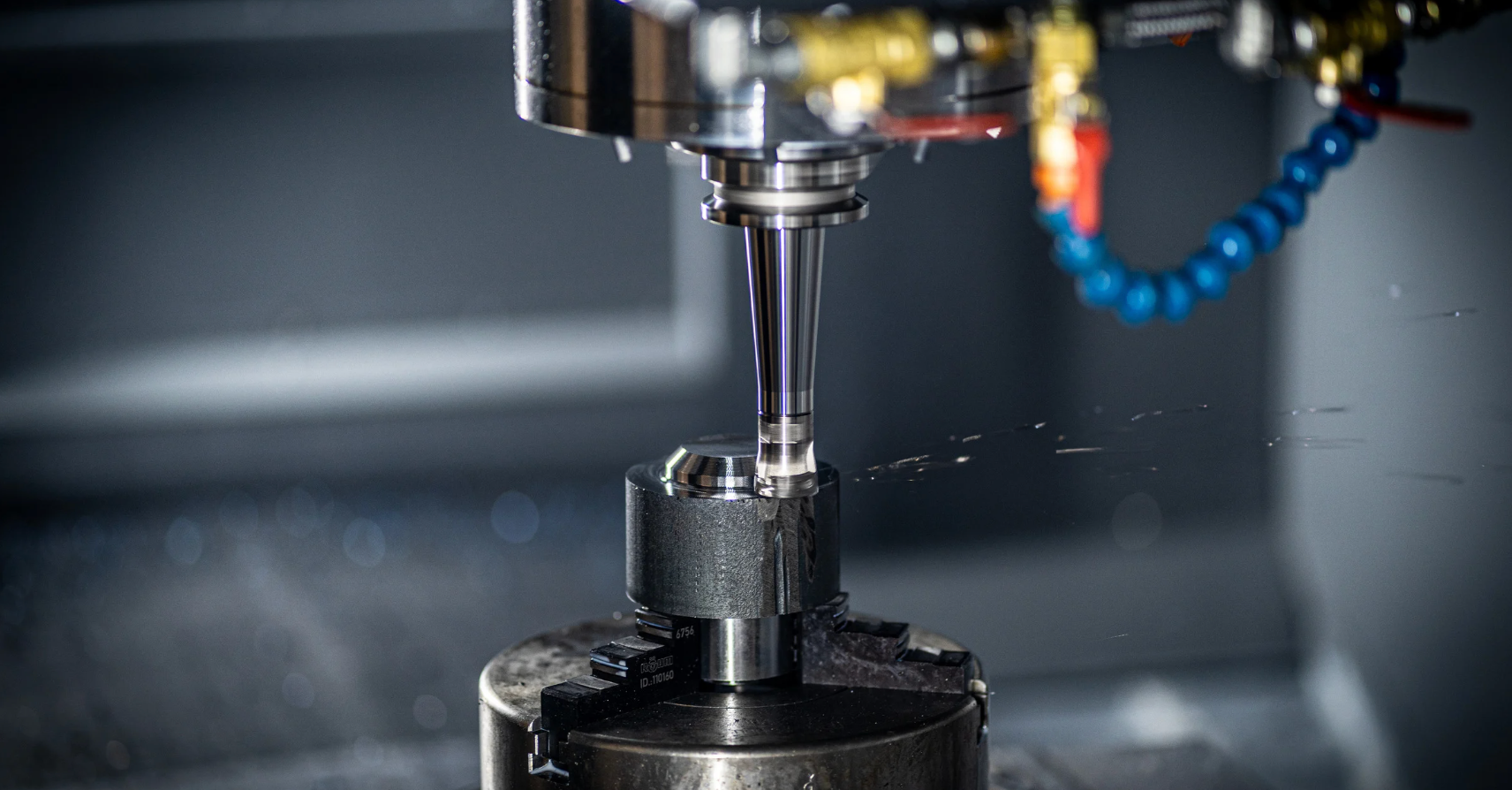

We are proud to announce that Modelcraft Co.has been recently featured by CONNSTEP for our continuous improvement initiatives. Since 1965, Modelcraft has been dedicated to manufacturing precision-machined parts for the medical, aerospace, and commercial industries. Under the leadership of President and CEO Richard Merlino and co-owner David Hill, our company continues to strive for excellence and innovation.

To enhance our operational and financial performance, we have incorporated Lean manufacturing techniques into our processes, particularly focusing on increasing the productivity of our milling department. With the valuable guidance of CONNSTEP, we embarked on a PRIME (Process Re-engineering for Increased Manufacturing Efficiency) project. This Lean manufacturing study, funded by the Connecticut Energy Efficiency Fund and administered by Eversource Energy, has helped us improve productivity and energy efficiency.

Rich Merlino, our President & CEO, shared his insights on the project, emphasizing the significance of employee engagement:

“The biggest lesson we learned from this project is the importance of employee engagement. As more employees became involved, they saw the benefits of the improvements firsthand. They enjoyed sharing ideas, being heard, and seeing their suggestions implemented. It was a rewarding experience for everyone.”

Project Impact

- $1,000,000 in Retained Sales

- 6 Jobs Created/Retained

- $90,000 in New Investments

- $600,000 in Cost Savings

For the full story and detailed insights, read the complete case study here.

Recent Articles