The Art and Science of Assembly in Precision Manufacturing

In the world of precision manufacturing, assembly is both an art and a science. At Modelcraft Co., the process of assembling components into a finished product goes beyond simply putting pieces together. It requires expertise, attention to detail, and a methodical approach to ensure each part works harmoniously within the final product.

The Importance of Assembly in Precision Manufacturing

Assembly is the bridge between individual components and the final product, impacting both functionality and quality. Whether for medical, aerospace, or commercial applications, the smallest misalignment can compromise performance. At Modelcraft Co., we understand that our clients rely on us to deliver components that meet exact specifications, enabling their products to perform with utmost reliability and precision. Assembly is where these expectations are met—and often exceeded.

The Science of Assembly: Ensuring Consistency and Accuracy

Precision assembly relies on standardized processes and cutting-edge technology. With AS9100D and ISO 9001:2015 certifications, Modelcraft Co. maintains stringent quality control systems, ensuring that each step of the assembly process adheres to rigorous standards. Our team uses advanced equipment to verify the accuracy of each assembled component, guaranteeing that each unit is identical in quality and precision.

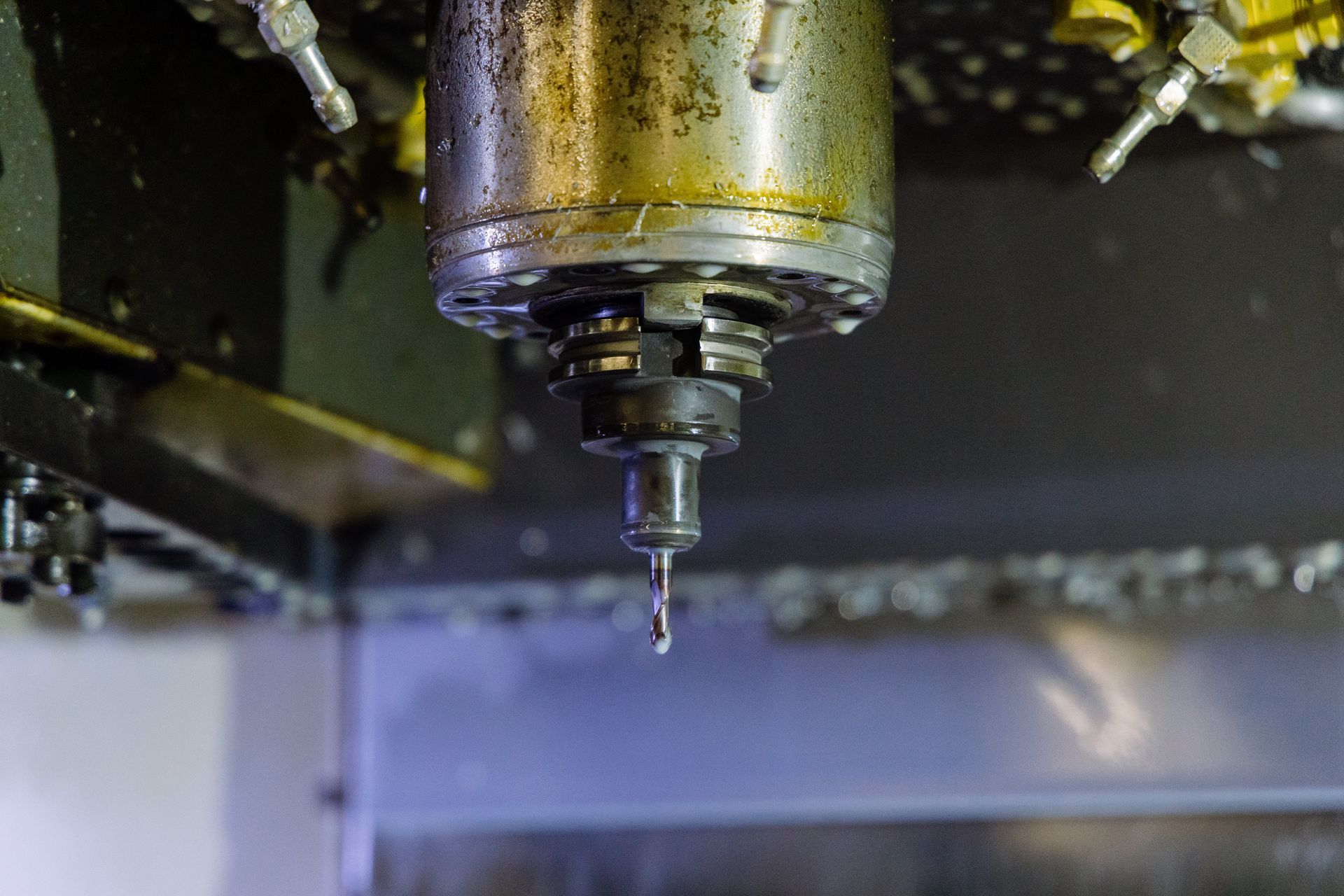

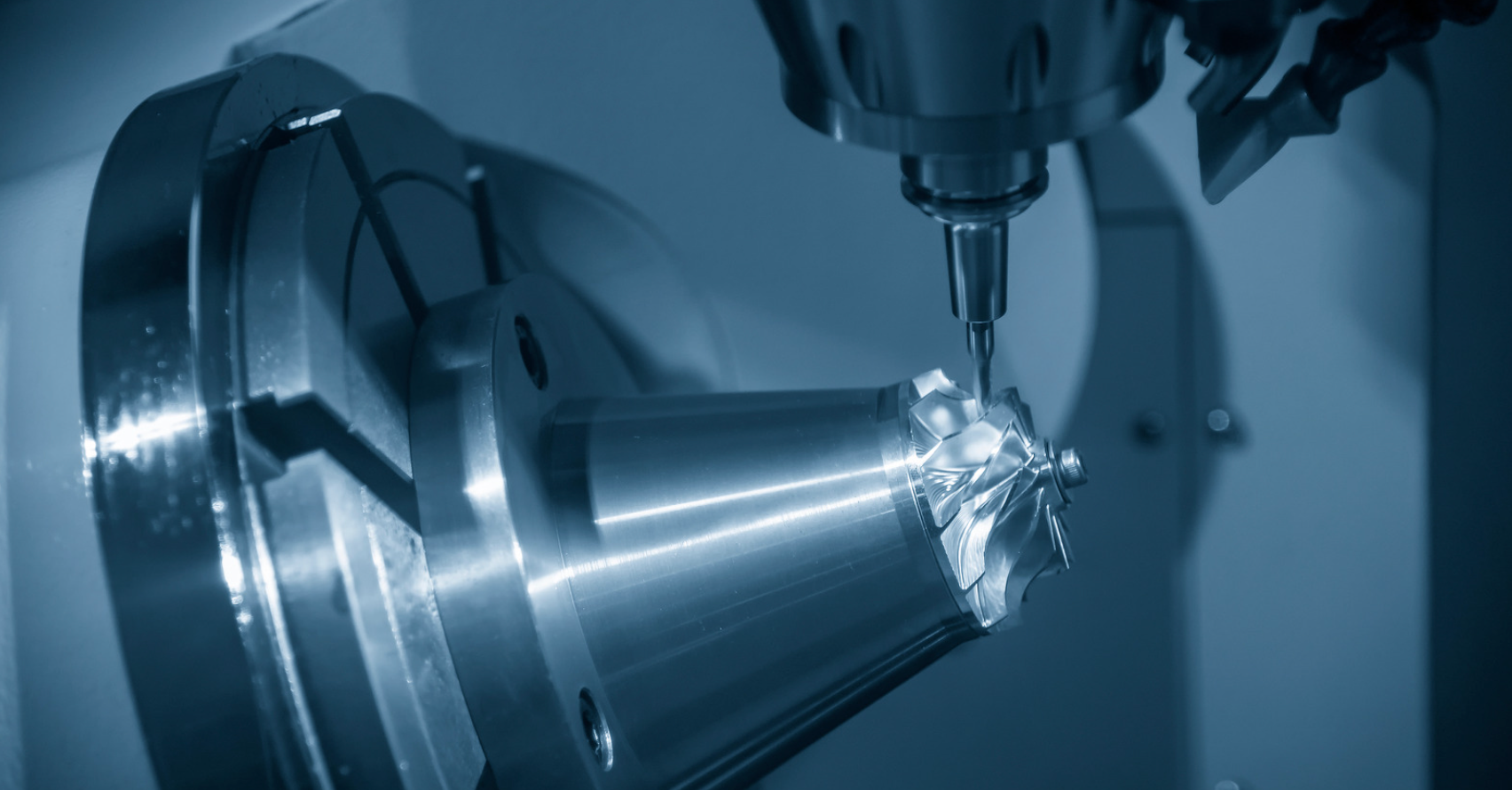

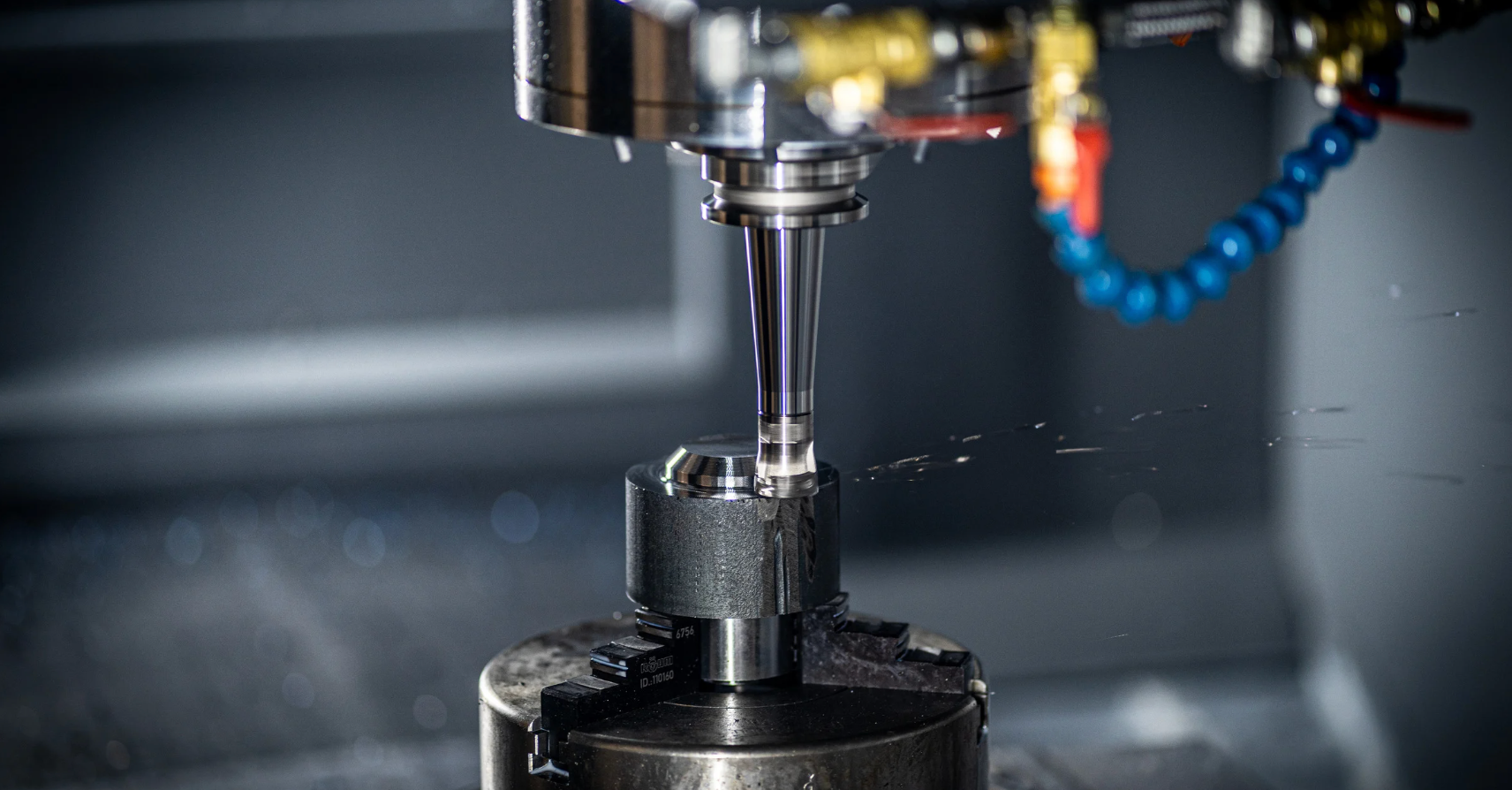

Technology plays a vital role in our assembly process. By integrating automated tools and machines, we can achieve high levels of precision that are simply unattainable by hand. This machinery allows us to maintain tight tolerances, crucial for small, high-precision components.

The Art of Assembly: The Human Touch in Precision Manufacturing

While technology enhances our assembly process, the expertise of our team is irreplaceable. Our highly-trained staff brings decades of experience to each project, offering the skill and intuition that only years in the field can cultivate. Assembly, especially for small components, requires steady hands, patience, and an eye for detail. Every part is examined by skilled technicians, who catch nuances that might escape even the most sophisticated machinery.

A Collaborative Process

At Modelcraft Co., we believe that successful assembly is a collaborative process. We work closely with our clients to understand their unique requirements, from specific component tolerances to final product functionality. Our assembly team plays an essential role in this collaboration, identifying potential improvements and ensuring that the end product meets or surpasses expectations.

Innovation Meets Experience at Modelcraft Co.

For almost 60 years, Modelcraft Co. has been perfecting the art and science of assembly. By combining innovative technology with experienced craftsmanship, we deliver precise, reliable, and high-quality components to our clients across various industries. Assembly may be one part of the manufacturing process, but it is where all other steps come together, culminating in products that enable our customers' success.

Assembly at Modelcraft is more than a process; it’s a commitment to excellence in every detail. Contact us today.

Recent Articles