The Role of Advanced Machining in the Medical Industry: Precision Parts Saving Lives

In the medical industry, precision and reliability aren’t just standards—they’re lifesavers. From surgical instruments to life-supporting devices, the parts used in medical equipment demand an exceptional level of accuracy. Advanced machining plays a critical role in this field, providing the precision components that ensure medical tools function flawlessly. At Modelcraft Co., we understand the importance of this responsibility, producing high-quality, precision-machined parts that ultimately contribute to saving lives.

Precision and Accuracy: The Heart of Medical Machining

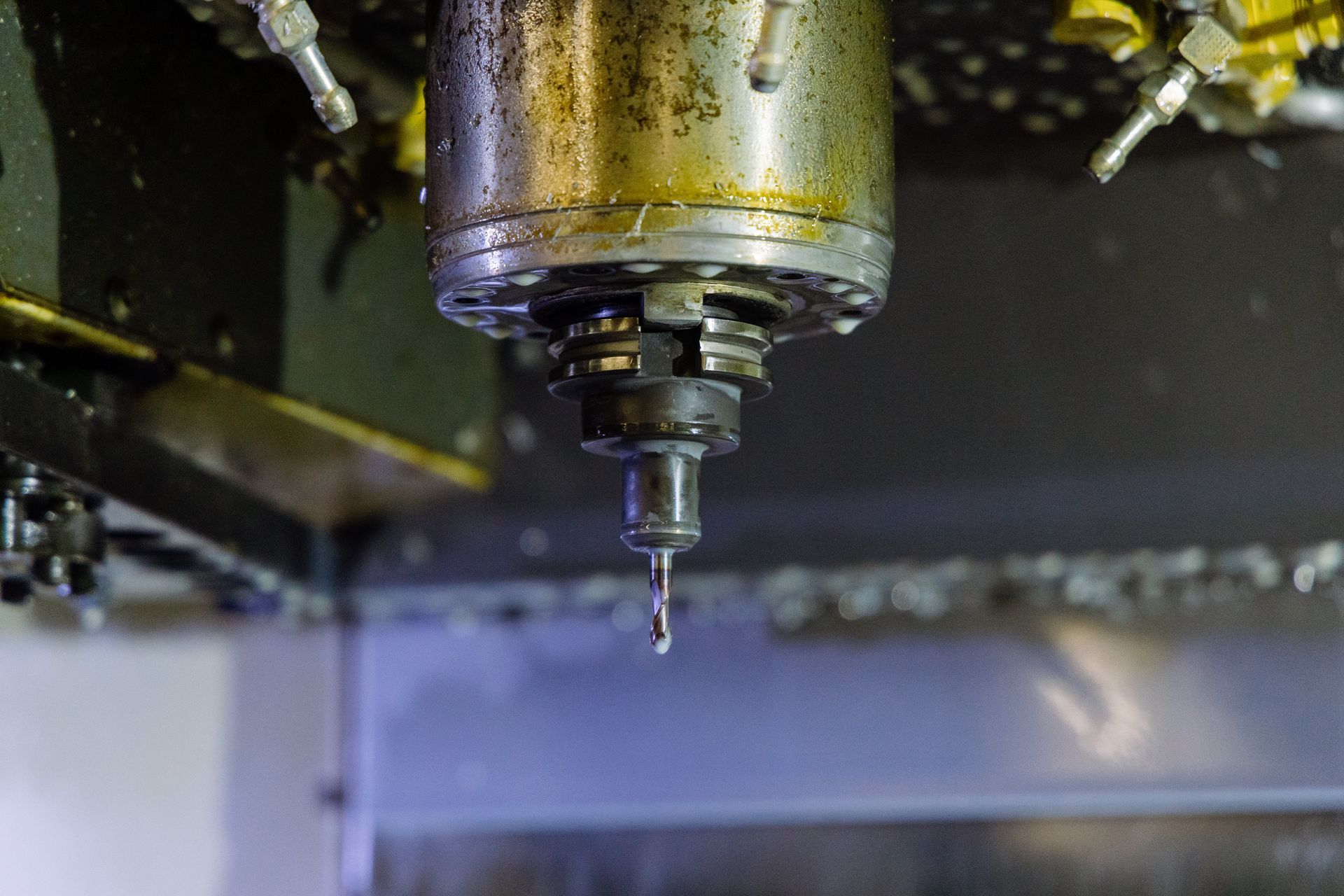

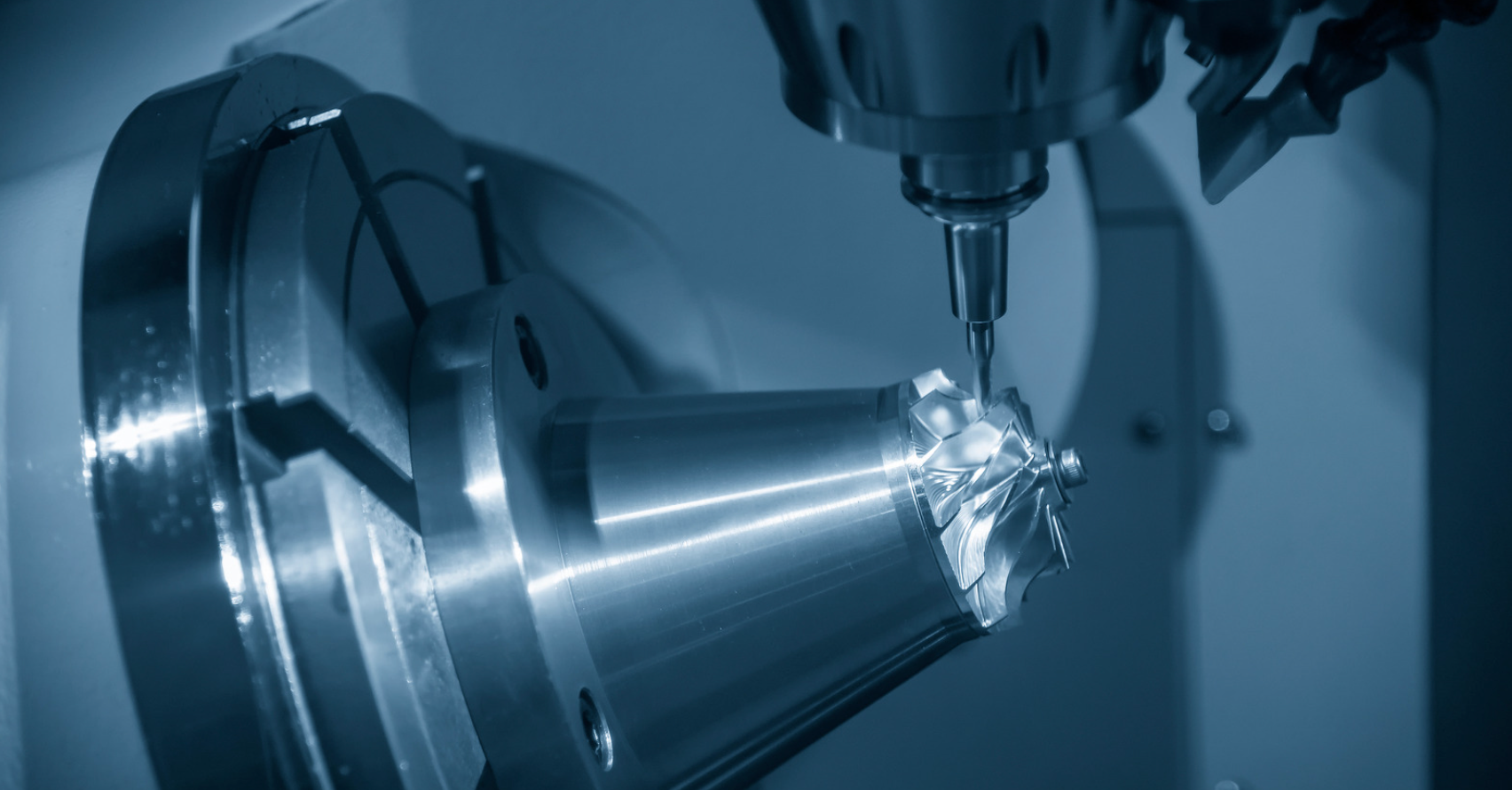

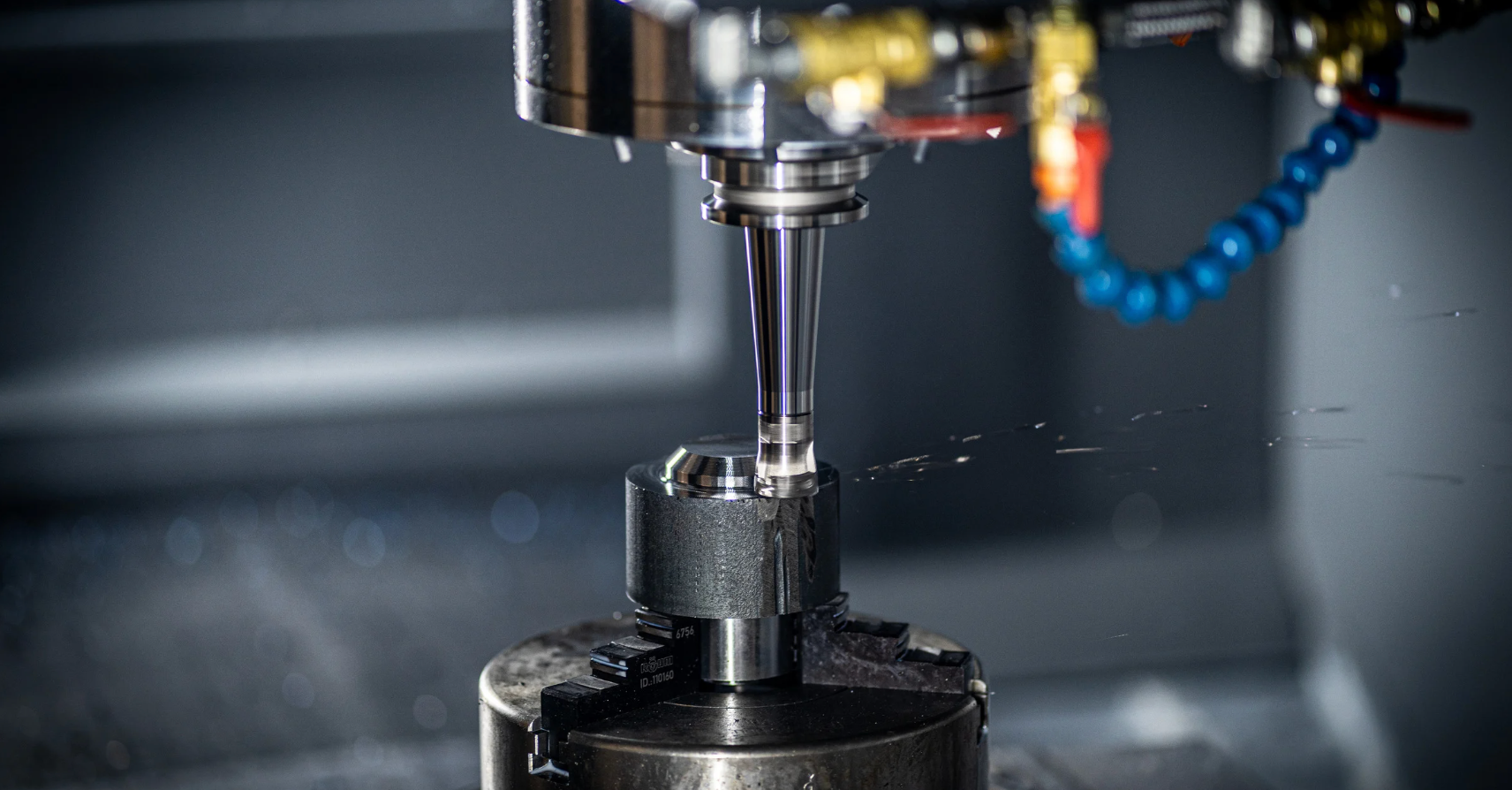

The medical industry requires parts that meet incredibly tight tolerances, often within microns, to ensure optimal performance and safety. For instance, surgical tools, implants, and diagnostic devices must operate seamlessly to avoid any risk to patients. A single flaw in any component could compromise the function of an entire medical device, endangering lives. With advanced CNC machining, Modelcraft Co. produces components with the utmost precision, consistently meeting the stringent requirements of medical applications.

Supporting Life-Saving Devices with Advanced Machining

Medical devices often contain complex assemblies that rely on micro-components machined to exact specifications. Devices like pacemakers, ventilators, and imaging equipment each consist of numerous intricate parts that must fit together perfectly. These parts must not only perform reliably but also withstand sterilization and rigorous use. At Modelcraft Co., we utilize advanced machining processes such as milling, turning, grinding, and wire EDM to create parts that meet these rigorous demands while maintaining top-tier durability.

Materials for Medical Machining: Durability Meets Biocompatibility

Medical components frequently need to be crafted from materials that are both durable and biocompatible. Metals like titanium, stainless steel, and specialized alloys are commonly used in the industry due to their strength and resistance to corrosion. These materials also need to be compatible with the human body, as they’re often used for implants or components in close contact with tissues. Modelcraft Co. carefully selects and machines materials that align with these critical requirements, ensuring both patient safety and component longevity.

Quality Control: Ensuring Zero-Defect Components

Quality control is paramount in medical machining, where there is zero tolerance for defects. Modelcraft Co. is AS9100D and ISO 9001:2015 certified, adhering to the highest quality standards in every part we produce. Our comprehensive inspection processes involve state-of-the-art equipment that checks each part against rigorous specifications, ensuring every piece aligns with the required standards. This commitment to quality minimizes risks, giving medical professionals confidence in the tools and devices they rely on.

Innovation in Medical Machining: Constantly Pushing Boundaries

As medical technology advances, so does the need for innovation in precision machining. At Modelcraft Co., we are dedicated to keeping pace with these advancements, investing in the latest machining technologies and continuously refining our processes. Our team’s expertise allows us to produce increasingly complex components, supporting new, innovative medical devices that enhance patient care and outcomes.

Modelcraft Co.: Precision Machining with a Purpose

For nearly six decades, Modelcraft Co. has been at the forefront of precision machining, proudly contributing to the success of the medical industry. Our advanced machining capabilities enable us to deliver the highest quality components, ensuring that every part performs exactly as it should. When lives are on the line, there is no room for error, and we are committed to the accuracy, reliability, and quality that the medical industry demands.

At Modelcraft Co., we’re not just creating parts—we’re supporting the medical industry’s mission to save lives, one precisely machined component at a time. Contact us today.

Recent Articles